- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Processing> The pasta macaroni machine keeps acclaiming

The pasta macaroni machine keeps acclaiming

2021-11-03 14:10:46Pasta Macaroni Making Machine is a high-tech screw extruder designed with advanced extrusion technology. It integrates raw material mixing, extrusion molding, drying and cooling, and packaging finished products. It has a high degree of automation and assembly line production, which can be operated in large quantities. Due to the advanced extrusion technology, the extrusion molding effect of the final product is very good.

Pasta macaroni is one of the pasta types. The world of pasta can be described as rich and varied. There are countless varieties of it. With the combination of sauces, thousands of pasta dishes can be made. The uniqueness of macaroni is that it has colors in appearance and more colorful performance in taste.

Pasta Macaroni Making Machine is a high-tech screw extruder designed with advanced extrusion technology. It integrates raw material mixing, extrusion molding, drying and cooling, and packaging finished products. It has a high degree of automation and assembly line production, which can be operated in large quantities. Due to the advanced extrusion technology, the extrusion molding effect of the final product is very good.

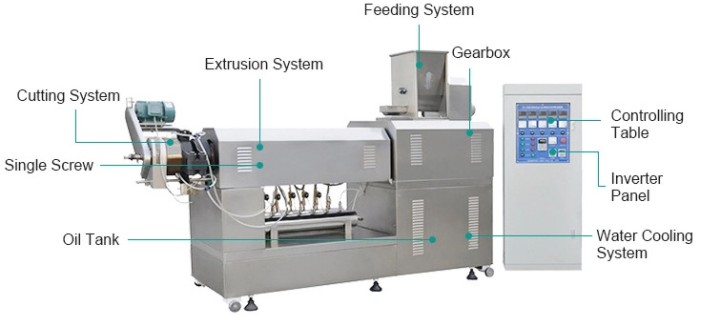

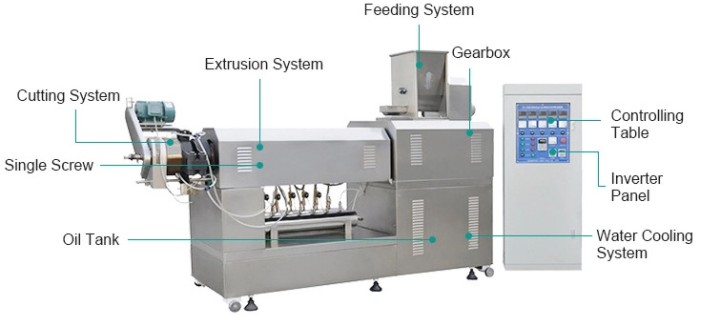

The macaroni production line is characterized by a fully automatic control system, which is very convenient to adjust various shapes and is widely used in macaroni production. In the whole production line, the most important part is the screw extruder, which guarantees the final extrusion molding effect of the product, can carry out continuous output, and cooperate with other machine parts to form a complete macaroni production line.

Features of pasta macaroni machine:

1. Linear structure, simple operation, convenient installation and maintenance.

2. Using unique single screw extrusion technology, exquisite workmanship.

3. High degree of operation automation and high degree of intelligence can improve work efficiency.

4. Advanced frequency control technicians, stable work and less power consumption.

5. Pneumatic components, electrical components, and operating components all adopt world-leading brand-name components.

Process (Frying): Mixer---Single-screw extruder---Cooling machine---Dryer---Fryer---Taste-up machine---Single roll

Process (not fried): Mixer---screw conveyor---screw extruder---cutting machine---dryer---cooling conveyor

Technical parameters of pasta macaroni machine:

|

Model |

A-100 |

|

Install the Power Supply |

110kw |

|

Power Consumption |

80kw |

|

Output |

100-150kg/h |

|

Size |

19000×2000×2200mm |

The spaghetti macaroni machine has low energy consumption and high output capacity. As long as you follow the correct usage method during the operation, you can maximize its advantages and get the perfect production effect. In addition, it has a variety of models to choose from, you can buy a whole production line, or you can purchase its supporting equipment according to your needs.

The pasta macaroni production line is mainly composed of a mixing system, an extrusion system, a cutting system, a drying system, a cooling system, and a packaging system. The various systems cooperate with each other to complete the production of macaroni. In addition to the production of macaroni, other products can also be produced. By changing the mold, the shape of the product can be varied.

The scope of application of this pasta macaroni machine is very wide. Unlike the previous production process, it is relatively simple. The design of this equipment has been greatly improved in the process, and all aspects have been greatly improved and more satisfied. Demand from food processing plants. The pictures above are some examples of the products. It can be seen that the products have the characteristics of various types, various shapes, and good molding effects.

Once the Pasta Macaroni Making Machine was sold, many customers rushed to buy it. They all reported that this machine performed perfectly in all aspects, not only was it beautiful in appearance, reliable in quality, and very efficient in production. Today, the production line has been sold all over the world and has been continuously praised. Its development prospects are very broad.

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines