- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Company News> What Is Corn Flakes Production Line

What Is Corn Flakes Production Line

2023-06-26 10:32:35Corn flakes production line is an automated manufacturing system for producing corn flakes grains. The line typically consists of multiple machines and processes that work together to produce cornflakes from ingredients such as cornmeal, sugar and salt. The first stage of a corn flakes production line involves mixing the ingredients in large silos. From there, the mixture is conveyed to a cooker/extruder, where it is heated and the ingredients are mixed to create a cooked dough. The cooked dough is then shaped and flattened using a rolling machine, and cut into small pieces using a cutter. The cut slices are then baked in an oven to give it its characteristic golden brown color, before cooling and packaging for sale. The entire process is usually controlled by a computerized system to ensure consistent production and quality. Overall, the corn flakes production line is a highly automated and efficient system that can produce corn flakes grains on a large scale.

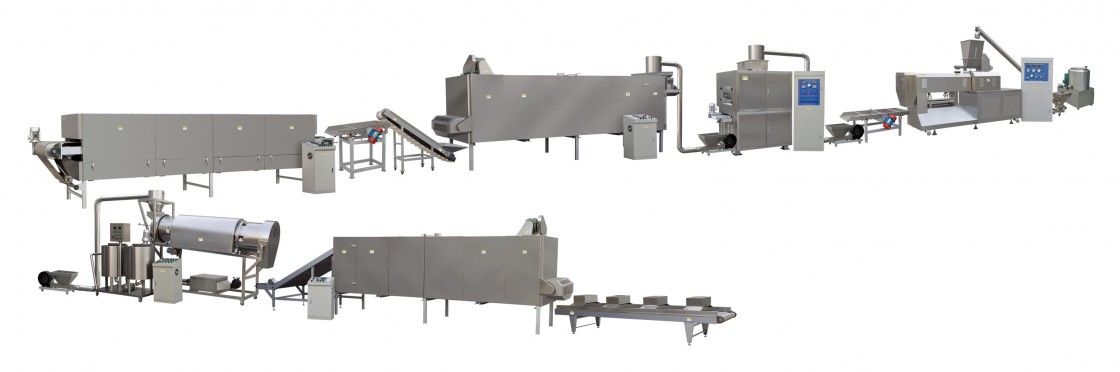

The Flowchart Of Corn Flakes Production Line

- Mixer --- 2. screw conveyer --- 3. Twin-screw extruder --- 4. Cooling Conveyor --- 5. Air conveyor --- 6. Flaking Machine --- 7. Air Conveyor --- 8. Pre-dryer --- 9. Hoister --- 10. Vibrate Feeder --- 11. Baking Machine --- 12. Sugar Sprayer --- 13. Multi-layer Oven --- 14. Cooling Conveyer --- 15. Packaging Machine

The Function Of Corn Flakes Production Line

A cornflakes production line is a highly automated sequential system consisting of various machines and processes for the production of cornflakes, a popular breakfast cereal.

A production line typically includes the following stages:

- Cleaning And Screening: The raw corn kernels go through a cleaning process to remove impurities such as stones, dust and foreign matter. They are then sorted to ensure only high-quality kernels are used.

- Soaking: Soak the clean corn kernels in water to soften them for the later milling process. Enzymes can be added to break down the starch and improve the texture of the corn flakes.

- Grinding: Grind the soaked corn kernels into fine corn flour or grits with a special mill. This step breaks down the structure of the kernel and releases the starch.

- Mixing: Combine the cornmeal or meal with the water, sugar, salt, and other ingredients to form a dough-like mixture. Mix it thoroughly to ensure a homogeneous mixture.

- Cooking: Cook the mixture in a steamer or extruder. The heat from the steam or the direct expansion of the mixture causes the starch to gelatinize, forming a pliable mass.

- Sheeting: Pass the cooked corn dough through sheeting rollers to flatten it into sheets of uniform thickness. The flakes are then cut to the desired size using a rotary cutter.

- Drying: Dry the corn flakes with hot air or an oven to reduce the moisture content and achieve the desired crispness. This step also extends the shelf life of the product.

- Toasting: Some nachos may be toasted to further enhance their flavor and texture. This step involves passing the flakes through a roasting oven, where they are heated briefly until they acquire a golden brown color and a characteristic toasty flavour.

- Coating And Thickening: An optional process includes coating the corn flakes with a coating of sugar, honey, cocoa or other spices. These flakes may also be enriched with vitamins, minerals, or other nutritional additives for additional health benefits.

- Cooling And Packaging: The corn flakes are cooled by fans or chillers to prevent moisture absorption. They are then weighed, packaged and sealed into boxes, bags or other containers for distribution and sale. Automated packaging machines ensure efficiency and accuracy.

Efficient conveyor systems, quality control measures and automation are employed throughout the production line to ensure smooth operation, minimize waste, maintain high hygiene standards and achieve consistent product quality.

The Parameter Of Corn Flakes Production Line

|

Model |

Installed Power (kw) |

Power Consumption (kw) |

Output

(kg/h) |

Size (L*W*H) (mm) |

|

LY65 |

140kw |

90kw |

120-150kg/h |

39000*1200*2200rnn |

|

LY70 |

160kw |

120kw |

180-220kg/h |

41000*1500*2200nm |

|

LY85 |

190kw |

140kw |

300-500kg/h |

43000* 3500*4300mm |

|

LY90 |

240kw |

190kw |

800-1000kg/h |

65000* 5000*4300mm |

The Advantages Of Corn Flakes Production Line

|

Improve Efficiency |

The cornflakes production line is designed to simplify the entire manufacturing process, thereby increasing productivity and efficiency. Automated machines and sequential processes enable high throughput with minimal physical labor. |

|

Stable Quality |

The production line follows the standardized process and precise measurement to ensure the consistent quality of each batch of corn flakes produced. This is critical to building customer trust and maintaining your brand's reputation. |

|

Cost-Effectiveness |

The use of production lines helps to reduce labor costs as it requires fewer workers as compared to manual production methods. In addition, the equipment used in the production line is specially designed for high durability and long life, minimizing maintenance and replacement costs. |

|

Improve Food Safety |

With proper quality control measures and automation systems, the production line can minimize the risk of contamination and ensure food safety. Strict hygiene practices can be implemented throughout the production line, including regular cleaning and disinfection of machinery and processing areas. |

|

Increased Productivity |

The automated nature of the cornflakes production line allows for faster processing times and higher output. This increases productivity and enables manufacturers to efficiently meet market demands. |

|

Flexibility |

The production line can be designed to accommodate different variations of cornflakes, including various shapes, flavors and textures. This flexibility enables manufacturers to cater to different consumer preferences and market trends. |

|

Energy Efficiency |

Modern corn flake production lines have energy saving features such as efficient heating and cooling systems and optimized machinery. This helps reduce energy consumption and environmental impact. |

|

Traceability |

Through the use of automated systems and effective record keeping, production lines can achieve better product traceability. This is critical for quality control, managing recalls and ensuring compliance with food safety regulations. |

|

Scalability |

The cornflakes production line can be easily scaled up or down to meet changing market demands. This flexibility enables manufacturers to adjust production levels without significant investment or process disruption. |

|

Innovation Opportunities |

The production line provides a platform for continuous improvement and innovation. Manufacturers can evaluate and optimize various processes, experiment with new ingredients or technologies, and introduce new product variants to remain competitive in the market. |

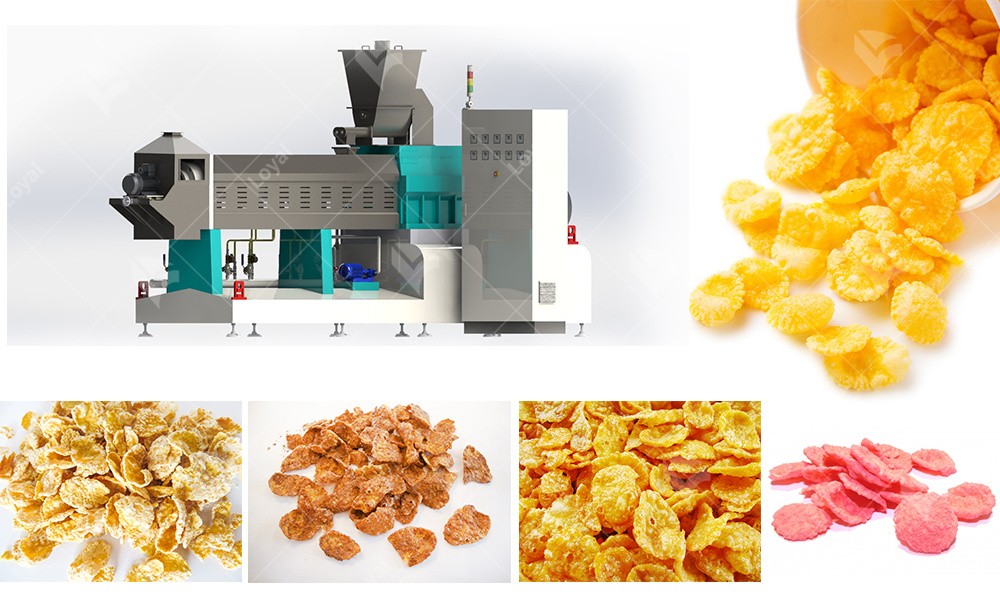

Corn Flakes Product Display

Nachos are a popular breakfast cereal made from toasted corn flakes. They were originally invented by John Harvey Kellogg in the late 19th century as a healthy, convenient breakfast option. Today, nachos are produced by several brands and have become a staple in households across the globe.

The main features of cornflakes are:

|

Baked Slices |

Corn flakes are made by rolling and roasting corn kernels. This process gives them a crispy texture and golden brown color. |

|

Nutritious |

Corn flakes are often rich in vitamins and minerals, such as iron, folic acid, and niacin. They are usually low in fat and are a good source of carbohydrates and fiber. |

|

Versatility |

Nachos can be eaten in a variety of ways. They're often served with milk, yogurt, or fruit, but can also be used in recipes like granola bars, cookies, or as a crunchy topping for salads. |

|

Wide Variety |

Different brands offer a range of nachos in different shapes, sizes and flavors. Some variations may be plain, while others may have added sugar, honey, or other flavorings. |

|

Packaging |

Cornflakes are usually sold in boxes or bags to keep them fresh. Packaging usually includes branding, nutritional information, serving advice, and storage instructions. |

When purchasing cornflakes, consider factors such as taste preference, nutritional content and any dietary restrictions. Some brands may also offer gluten-free or organic options for those with specific preferences or dietary needs. Cornflakes are a convenient and popular breakfast choice because of their simplicity, versatility and nutritional value.

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines