- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Company News> What Is Nutrition Powder Production Line

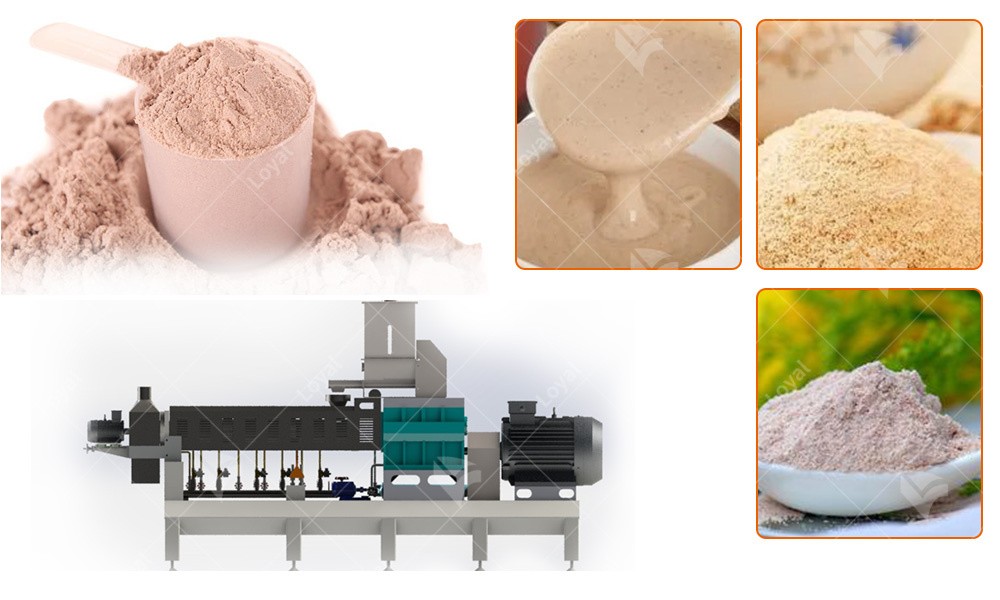

What Is Nutrition Powder Production Line

2023-06-21 15:32:40Nutrition powder production line is a production equipment designed for the production of nutrition powder or formula milk powder. The production line usually includes various machinery and equipment that perform different processes, such as mixing, grinding, drying and packaging. The production line begins with the preparation of raw materials, including vitamins, minerals, proteins, carbohydrates and other nutrients. These ingredients are then mixed together in predetermined proportions using mixing equipment. The mixture is then milled to obtain a uniform particle size. Next, the pulverized mixture is dried using a drying device such as a spray dryer or a fluidized bed dryer. This process involves removing water from the mixture to produce a dry powder. The dry powder is then sieved to ensure a uniform particle size and to eliminate any lumps. The last step in the production line is the packaging of nutritional powder. The powder is typically filled into a container, such as a sachet, jar or jar, and sealed for consumer use. The packaging process may also involve labeling, coding and boxing. Overall, nutritional powder lines are designed to efficiently mass-produce nutritional powder or formula while maintaining quality, consistency and safety standards.

The Flowchart Of Nutrition Powder Production Line

- Screw Conveyor --- 2. Ribbon Mixer --- 3. Screw Conveyor --- 4. Double Screw Extruder With Cooling System --- 5. Air Conveyor --- 6. Drying Oven --- 7. Air Conveyor --- 8. Crushing Machine With Dust Pelletizing System --- 9. Air Conveyor --- 10. Blending Mixer --- 11. Packaging

The Function Of Nutrition Powder Prouction Line

- Screw Conveyor: Screw conveyor can not only convey on the level but also by any angel these materials can be conveyed in the stainless steel roller without leaking, dust pollution; meanwhile it can send the self-mixer to the feeding machine or the conditioner and directly send the discharge hole of the inflating extruder.

- Ribbon Mixer: The powder is mixed with other ingredients to create a homogeneous blend. The mixing process is important to ensure that the powder has a consistent nutrient profile, texture, and flavor.

- Double Screw Extruder With Cooling System: The powder is mixed with other ingredients to create a homogeneous blend. The mixing process is important to ensure that the powder has a consistent nutrient profile, texture, and flavor.

- Air Conveyor: Used to carry products to the next device.

- Drying Oven: After extrusion, the product is dried and cooled to remove any moisture and improve its shelf life. Different drying methods can be used, including spray drying, freeze drying, and oven drying.

- Crushing Machine With Dust Pelletizing System: Grinding the extruded granules into required sizes of powder or smaller granules with the help of mesh screen.Two mesh screens are provided for free.

- Blending Mixer: The powder is mixed with other ingredients to create a homogeneous blend. The mixing process is important to ensure that the powder has a consistent nutrient profile, texture, and flavor.

- Packaging: Finally, the dried powder is packaged in a suitable container and labeled for distribution. Packaging is an important step to ensure that the product remains fresh and free from contamination during transportation and storage.

The Parameter Of Nutrition Powder Production Line

|

Model |

Installed Powder (Kw) |

Powder Consumption (Kw) |

Output (Kg/h) |

Size (L*W*H) |

|

LY65 |

88kw |

62kw |

120-150kg/h |

19000*1200*2000mm |

|

LY70 |

142kw |

99kw |

200-250kg/h |

24000*1200*2000mm |

|

LY85 |

160kw |

130kw |

300-500kg/h |

28000*1500*2000mm |

|

LY90 |

220kw |

154kw |

800-1000kg/h |

29000*2500*2200mm |

|

LY95 |

220kw |

154kw |

1000-1500kg/h |

30000*2500*3500mm |

The Advantage Of Nutrition Powder Production Line

|

Improve Efficiency |

The nutritional powder production line is designed to automate and simplify the manufacturing process. By using professional machinery and equipment, the production line can handle a large amount of raw materials and produce nutritional powder at a faster speed than manual production. |

|

Stable Quality |

The production line follows standardized processes and formulas to ensure stable quality. This reduces the risk of human error and ensures that the nutritional powder meets the required specifications and nutritional content. Quality control measures can be implemented at various stages of the production line to monitor and maintain product quality. |

|

Cost-Effective |

By utilizing automated and efficient production methods, nutritional powder production lines can help reduce labor costs and increase overall productivity. The line also minimizes material waste and optimizes resource utilization, saving costs in the long run. |

|

Scalability |

The nutritional powder production line can be easily scaled up or down to meet changing market demands. With the ability to handle large quantities of ingredients and produce nutritional powders in batches, manufacturers can adapt to changing consumer preferences and market trends. |

|

Safety And Hygiene |

The production line is designed to meet strict hygiene standards to ensure the safety and integrity of nutritional powder. It includes features such as easy-to-clean surfaces, closed systems to prevent contamination, and compliance with food safety regulations and standards. |

|

Product Innovation |

The nutritional powder production line provides manufacturers with the flexibility to develop and launch new products or variations of existing products more efficiently. With the ability to control and adjust ingredient ratios, taste and texture, manufacturers can innovate and cater to different market segments and consumer preferences. |

|

Enhanced Traceability |

Production lines can incorporate traceability systems and processes, such as batch tracking and quality control measures, to ensure that each batch of nutritional powder can be traced back to its source and manufacturing process. This facilitates effective quality control, recalls and compliance with regulatory requirements. |

Nutrition Powder Product Display

Nutrient powder products are convenient and versatile dietary supplements that provide essential nutrients in powder form. It's designed to be mixed with liquids like water, milk, or juice, or added to foods like smoothies, yogurt, or oatmeal.

Here are some key features and benefits of nutritional powder products:

|

Comprehensive Nutritional Support |

Nutrient powder products are formulated to provide a broad range of essential vitamins, minerals, protein, fiber and other beneficial compounds. They are often designed to meet specific dietary needs, such as providing extra protein for muscle recovery or targeted nutrition for a specific health condition. |

|

Convenience |

Nutrition powder products are usually packaged in portable containers, which are convenient to carry around. They require minimal prep work and mix easily with liquids for a quick and nutritious meal or snack. |

|

Customizable Nutrition |

Many nutritional powder products are available in a variety of flavors and formulations to meet different preferences and dietary requirements. They can be customized for specific needs, such as low-carb, high-protein, vegan or gluten-free diets. |

|

Add Functional Benefits |

Some nutritional powder products may contain additional functional ingredients such as probiotics, antioxidants, herbs or adaptogens to enhance health benefits. These ingredients can support digestion, immune function, energy levels or stress management. |

|

Weight Management Support |

Nutrient powder products can be used as part of a balanced diet and daily exercise routine to support weight management goals. They can provide a satisfying and nutritious alternative to high-calorie meals or snacks. |

|

Supplementary Nutrition |

In some cases, it may be difficult for individuals to consume a balanced diet, such as during illness, recovery, or periods of high body demand, nutritional powder products can be convenient and effective to ensure adequate nutritional intake. |

|

Quality And Safety |

Reputable nutritional powder products are produced under strict quality control standards, ensuring that they are safe, properly labeled, and dosed accurately. Look for products that have been third-party tested to verify their quality and purity. |

It is important to note that nutritional powder products should not replace whole foods or a healthy diet, but rather serve as supplements to support overall nutrition and health. Before incorporating any dietary supplement into your routine, it is always recommended that you consult a healthcare professional to ensure it fits your specific needs and goals.

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines