- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Company News> What Is Biscuit Production Line

What Is Biscuit Production Line

2023-06-22 11:28:35A biscuit production line is a series of machines and equipment for the mass production of biscuits. It usually consists of multiple stages including mixing, shaping, baking, cooling and packaging. The line is designed to automate the biscuit manufacturing process, increasing efficiency and output. By adjusting the machines and ingredients used, different types of biscuits can be produced on the biscuit line, such as plain biscuits, cream biscuits or wafer biscuits.

The Flow Chart Of Biscuits Process Line

- Flour mixer --- 2. Dough cutting machine --- 3. Dough conveyor --- 4. Hard biscuit forming machine --- 5. Soft biscuit forming machine --- 6. Inlet oven conveyor --- 7. Intelligent Temperature Control Tunnel Oven

The Function Of Biscuits Production Line

The role of the biscuit production line is to produce biscuits efficiently, continuously and in large quantities. Some specific functions of the different stages in a biscuit production line include:

- Mixing: This stage involves mixing ingredients such as flour, sugar, fat, and flavorings in the correct proportions to form the cookie dough. The mixing process ensures even distribution of ingredients.

- Forming: At this stage, the dough is formed into the desired biscuit shape and size. This can be done in a variety of ways, such as a rotary former for plain biscuits or an extruder for sandwich biscuits.

- Baking: The formed biscuit dough is baked in the oven to make it crispy and enhance the flavor. Baking times and temperatures are carefully controlled to achieve the desired characteristics of the biscuits.

- Cooling: After baking, the hot biscuits need to be cooled to room temperature. Cooling systems, such as conveyor belts or cooling racks, are used to facilitate the rapid cooling process.

- Packaging: After the biscuits are cooled, they are automatically packaged. This may involve sealing the cookies in individual packages or putting them in boxes for bulk packaging. Packaging machines ensure product safety, freshness and attractive appearance.

Throughout the production line, quality control measures are implemented to ensure that the biscuits meet the required standards. This may involve monitoring parameters such as dough consistency, baking time and temperature, and final product weight and appearance. Overall, the function of a biscuit production line is to simplify the manufacturing process, increase productivity, maintain consistency, and produce high-quality biscuits.

The Parameter Of Biscuits Process Line

|

Model |

Capacity (kg/h) |

Finished Biscuit |

|

LY-400 |

150-200kg/h |

Soft biscuit,hard biscuit,sandwiching biscuit |

|

LY-600 |

400-500kg/h |

Soft biscuit,hard biscuit,sandwiching biscuit |

|

LY-800 |

600-800kg/h |

Soft biscuit,hard biscuit,sandwiching biscuit |

|

LY-1000 |

1000kg/h |

Soft biscuit,hard biscuit,sandwiching biscuit |

|

We can design according to customer factory and required. |

||

The Advantage Of Biscuits Production Line

|

Increased Efficiency |

The production line enables continuous, automated processes, reducing manual labor and increasing productivity. This increases throughput and reduces production time. |

|

Consistency And Quality Control |

Through the production line, the whole process can be strictly controlled and monitored to ensure the consistent quality of each batch of biscuits produced. This reduces variance and ensures that each biscuit is to the desired standard in terms of taste, texture, size and appearance. |

|

Cost Saving |

By optimizing the production process and reducing manual labor, the biscuit production line can save costs in the long run. Improving raw material usage efficiency, reducing waste and increasing yield can help reduce production costs. |

|

Flexibility And Customization |

The production line can be designed to accommodate various biscuit recipes and shapes, allowing the production of a wide variety of biscuit options. Multiple production lines can be set up for different product lines to achieve customization to meet specific market needs. |

|

Sanitation And Food Safety |

A properly designed production line can incorporate strict sanitation protocols and features to ensure food safety. This includes mechanisms to prevent cross-contamination, controlled temperature and humidity levels, and automatic cleaning systems. |

|

Scalability |

As demand grows, the production line can be easily expanded or modified to increase capacity. Additional machinery or production lines can be added to meet market demands without disrupting existing production processes. |

|

Traceability |

The biscuit production line adopts advanced technology and automation system, which can track and trace raw materials and finished products. This improves product traceability and enables efficient recall management if necessary. |

Overall, biscuit production lines have numerous advantages in terms of efficiency, quality control, cost savings, flexibility, food safety, scalability and traceability. These advantages help improve productivity, customer satisfaction and profitability for biscuit manufacturers.

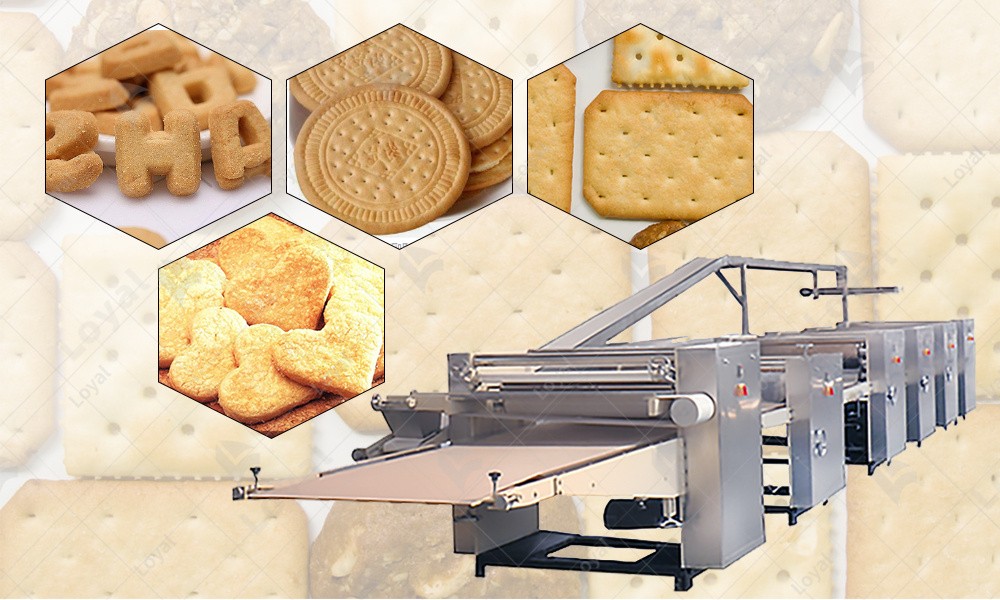

Biscuits Product Display

There are many types of biscuits, each with its own unique characteristics and taste.

The following are some popular types of cookies:

- Buttermilk Biscuits: These are a classic biscuit made with buttermilk for a rich flavor and a tender, flaky texture.

- Southern Biscuits: Known for their high butter and shortening content, Southern-style biscuits have a crispy exterior, fluffy interior, and a rich texture.

- Drop Cookies: Drop cookies are a quick and easy variation that simply drops the dough onto a baking sheet, no rolling and cutting required. They are usually softer and slightly denser than traditional biscuits.

- Cheese Crackers: These crackers are made by adding shredded or grated cheese to the dough, giving them a salty and cheesy taste.

- Sweet Cookies: Sweet cookies come in many forms, from simple sugar cookies to those flavored with spices, fruit, nuts, or chocolate chips. They are often enjoyed as a snack or dessert.

- Digestive Biscuits: Digestive biscuits are a semi-sweet biscuit originating in the UK. They are made with whole wheat flour, sugar and baking soda and are usually enjoyed with tea.

These are just a few examples, there are many other cookie variations around the world.

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines