- Shandong Loyal Industrial Co.,Ltd.

- Industrial Microwave Oven Food Extruder Machine Biscuit Making Machine

Home> Company News> Automatic Corn Flakes Processing Machine will be shipped to Indian

Automatic Corn Flakes Processing Machine will be shipped to Indian

2022-01-19 10:10:52Automatic Corn Flakes Processing Machine will be shipped to Indian by Shandong Loyal Industrial Co.,Ltd. , we provide latest information about the products regularly.

I have an old Indian customer who had already purchased a biscuit production line from loayl the year before last. He is very satisfied with our machines and after-sales service. He wants to expand his marketing scale this year and start a corn flakes production project. So he found us again. He expressed his trust in our machine. Through general communication and introduction, he soon made a second deal with us, and finally placed an order for a 500kg/h automatic corn flakes processing machine.

This Indian customer is a food processing factory. Since it has cooperated with a corn flakes brand this year, it is necessary to build a new factory. Since the Indian customer is a processing factory, when making corn flakes, the raw materials and recipes are all provided by the brand. Fang specified, so he sent me the ingredient list of the brand side. I said that our machine can be equipped with this kind of material, and Indian customers expressed their confidence.

|

Formula Of Automatic Corn Flakes Processing Machine |

|

|

Ingredient |

Proportion |

|

Corn Flour: |

26.6% |

|

Sugar: |

10% |

|

Butter: |

5% |

|

Water: |

25% |

|

Barley Extract: |

3% |

|

Baking Soda: |

10% |

|

Milk : |

15% |

|

Starch: |

10.4% |

|

Corn Flakes Manufacturing Process Flow Chart |

|

|

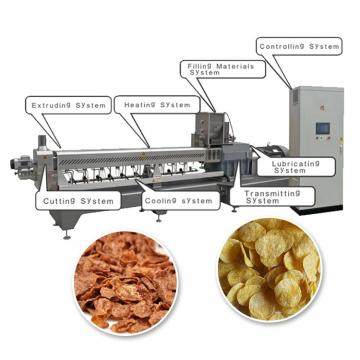

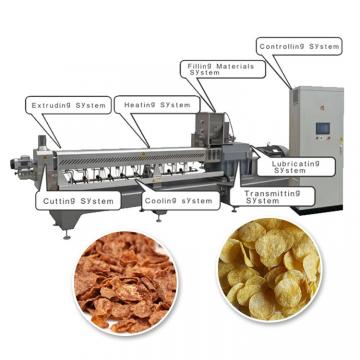

Mixer → Screw Conveyor → Twin Screw Extruder → Air Conveyor → Tablet Press → Air Conveyor → Dryer |

|

|

→ Elevator → Hot Air Baking Machine → Seasoning Machine → Dryer → Cooling Machine → Packaging Machine |

|

|

Mixer |

Premix Grains, Minerals And Vitamins, Salt, Milk Powder, Emulsifiers Are Fed, |

|

Twin Screw Extruder |

The Partially Cooked Product Is Introduced Into The Twin-Screw Extruder. |

|

Tablet Press |

After A Short Cooling Period, The Products Are Tempered, Cut And |

|

Hot Air Baking Machine |

They Are Then Transferred To A Dryer / Toaster And Cooled Before Being Stored And Packed. An Additional Coating Operation May Be Applied To Add,- For Example, A Sweet Syrup, Before Drying And Cooling. |

After referring to the ingredient list, I also provided some process and process drawings about the machine, and introduced their functions respectively. He said that when he used our oven before, he found our company's unique design for the oven, and felt that our home The quality of the oven is very good compared to other brands.

|

Corn Flakes Machine Capacity Available |

|||

|

Model |

LY70 corn flakes machines/processing line |

LY85 corn flakes machines/processing line |

|

|

Installed capacity |

166KVA |

263KVA |

|

|

Power |

110Kw |

200Kw |

|

|

Output |

120-150kg/h |

240-320kg/h |

|

|

Dimension |

45×3×4m |

48.5×5×4m |

|

In recent years, India has shown a growth model for imported mechanical and electrical machinery, and strives to implement the policy of opening to the outside world, encourage foreign investment, actively improve the investment environment, and increase investment policies. In terms of mechanical and electrical products, China is a major import and export country of mechanical and electrical products, and has certain technological advantages over India. Therefore, India imports more mechanical and electrical products from China. It is profitable for Indian clients to start this industry.

But the Indian customer was still worried that the product he made did not match the brand, so we produced it in our factory according to the ingredient list he provided, and we promised to provide him with free samples. He expressed his willingness to see the samples first, and a few days later , he received the sample and found that it was no different from the one provided by the brand, which made him not worried.

|

Our service Of 500kg/h Corn Flakes Machine |

|

|

High-Quality After-Sales Service |

Engineer Services For Overseas Machinery Services |

|

1.The distribution map requested by the buyer will be provided. 2.Process operation manual will be provided after delivery. 3.Provide 1 year complete warranty and lifetime maintenance services. 4.Free fragile spare parts will be sent out with the packing box. 5.The first installation can be completed by the equipped engineer. |

1.Provide free consultation service before, during and after sale. 2.Free project planning and design services. 3.Free debugging of equipment until everything is normal. 4.Free equipment maintenance and personal operation training. 5.Provide free new production process and formula. |

Automatic Corn Flakes Processing Machine Installed In Indian Customer Workshop

After I provided a more detailed information proposal, he finally accepted my proposal. A 500kg/h corn flakes production line was sold. The 28-day shipping schedule is just a few days away. He said that he will expand his scale and is looking forward to continuing to cooperate with us.

Corn Flakes Making Machine

Corn Flakes Making Machine Breakfast Cereal Making Machine

Breakfast Cereal Making Machine CORN FLAKES PRODUCTION PROCESS LINE 100T/DAY

CORN FLAKES PRODUCTION PROCESS LINE 100T/DAY BREAKFAST CEREAL PRODUCTION LINE

BREAKFAST CEREAL PRODUCTION LINE Instant Pasta Production Line

Instant Pasta Production Line 150Kw Fully Automatic Industrial Continuous Microwave Shrimp Drying Machine

150Kw Fully Automatic Industrial Continuous Microwave Shrimp Drying Machine Continuous Tunnel Honeysuckle Flower Drying Dehydrator Machine Tunnel Microwave Baking And Sterilizing Equipment

Continuous Tunnel Honeysuckle Flower Drying Dehydrator Machine Tunnel Microwave Baking And Sterilizing Equipment Automatic Microwave Frozen Meat Beef Thawing Machine

Automatic Microwave Frozen Meat Beef Thawing Machine