- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Processing> Do You Know The Application Of Pet Feed Extruder In High Temperature Environment?

Do You Know The Application Of Pet Feed Extruder In High Temperature Environment?

2020-09-18 08:57:44The lubricating oil should be replaced in season. It is the place to pay attention to in every season. Secondly, anti-freezing work must be done well. In the cold climate of the pet food extruder machine. The cooling water tank of the pet food extruder should be replaced in time with the cooling water and added antifreeze.

With people's pursuit of puffed food, automatic pet feed extruder machine and puffing technology are improving day by day. High-temperature puffing technology is a modern mechanical extrusion molding technology combined with an older fried puffing technology to produce puffing food. Dog food manufacturing equipment belongs to a kind of equipment for processing puffed food, such as rice, corn, soybean, wheat, etc. in daily life.

Its main working principle is that mechanical energy is converted into heat energy. The heat generated when the machine rotates is used to squeeze and cook the food. The most obvious feature of the puffing extruder food is its larger volume.

The lubricating oil should be replaced in season. It is the place to pay attention to in every season. Secondly, anti-freezing work must be done well. In the cold climate of the pet food extruder machine. The cooling water tank of the pet food extruder should be replaced in time with the cooling water and added antifreeze. Or the cooling water tank should be kept warm. And the cooling water tank should be cleaned in time after the end of each day and the residue should be drained Cooling water.

Electrical wiring and cables should be checked in time. Because in cold climates, severe shocks will cause short circuits or leakage accidents. So insulation treatment is also a must.

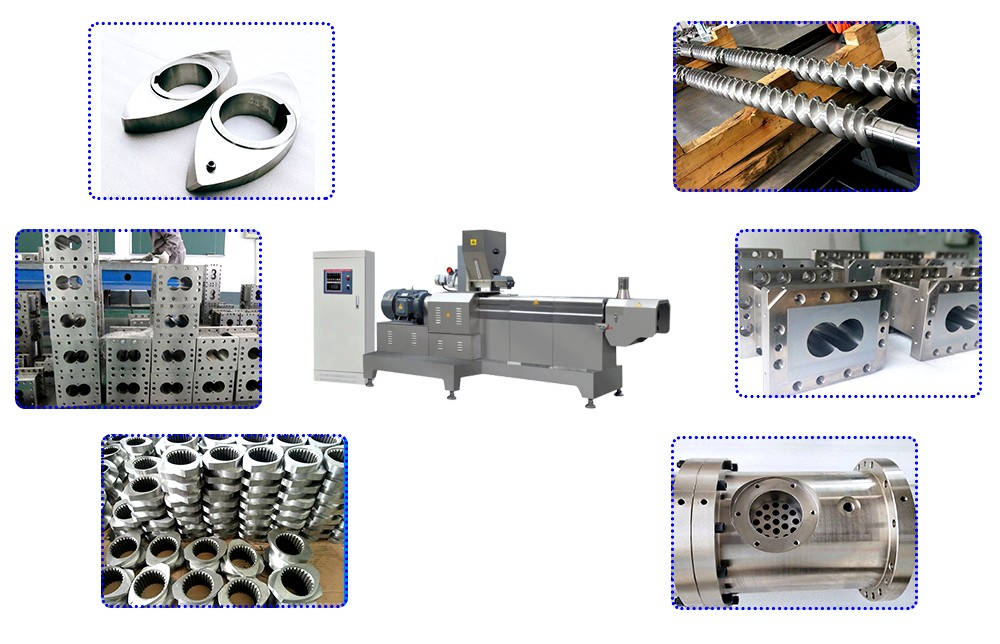

1. The main engine of the industrial pet feed extrusion adopts advanced frequency converter speed regulation technology. It makes the equipment powerful, running more stable and saving electricity. The screw of the feed extruder adopts alloy steel nitriding treatment. And the screw has a longer life. Individual equipment adopts a modular structure. It can be combined according to different needs.

2. A forced lubrication system is used to ensure a longer life span for the transmission part of the pet food production line. The automatic temperature control system can be used to make the temperature control more intuitive and the parameters more accurate.

3. The screw of the pet feed extruder has a self-cleaning function. There is no need to disassemble the screw for cleaning when it stops. Different screws and ratios of length to diameter can meet different production processes.

Pet Food Production Line

Pet Food Production Line Dog Treat Biscuit Making Machine

Dog Treat Biscuit Making Machine Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines