- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Processing> How to choose a right packaging machine?

How to choose a right packaging machine?

2020-07-07 12:42:05The packing machine supplier use different packag machine packing food, potato chips, candy, pistachios, raisins, Tangyuan, meat balls, peanuts, biscuits, jelly, candied fruit, walnut, pickles, frozen dumplings, almonds, salt, washing powder, solid drink, Cereals, such as pesticide particles particles Flake, short of powder and other items for sale.

How to choose a packaging machine and what are the basic conditions for choosing a packaging machine?

|

1 |

Packing speed |

|

2 |

Packaging film width or Packaging bag size |

|

3 |

Packaging Materials Typical materials are: CPP\PET OPP\PET PE aluminized film, etc. |

|

4 |

Measurement accuracy requirements |

|

5 |

Material properties Powders, granules, lumps, spheres, stickiness, water |

|

6 |

The proportion of materials |

|

7 |

Bag type Back seal bag/Pillow bag /Self-supporting bag/ Four-side bag /Vacuum bag, etc. |

|

8 |

Workshop height |

Notes on choosing a packaging machine:

|

The maximum length of sheet-shaped, strip-shaped, and disk-shaped materials exceeds 50MM, and the material blocking problem must be considered when selecting the shaper. |

|

The solution can be to use multiple feedings or add a pushing device (when using the pushing device, the customer must accept the scrap), multiple feedings will directly affect the packaging speed. |

|

Small particles, such as rice, sugar, millet, soybeans, etc., can be metered in the future using an opening and closing door turntable device. The measurement error is about 7%. You can also choose 2 bucket scale, 4 bucket scale and computer combination scale. The combination of computers is recommended to add a cross feeder. When packing soybeans, peanuts and other similar materials, the receiving hopper must be welded with bars to prevent the material from rotating and causing jams. |

|

Spherical products, with a diameter of more than 15MM and a single weight of more than 6 grams, can use a few grain discs according to customer requirements. If the individual weight is not uniform, but the overall weight requirements are accurate, you can choose a computer combination weigher. |

|

Conventional powder packaging Raw flour, rice flour, flour, milk powder, etc. can be measured with a screw, but the screw and spiral metering head should be selected according to the weight of the measurement. |

|

When selecting the angle-angle device, the nature of the material should be taken into account. If it is puffed food, it is easy to block the material. |

|

Disadvantages of measuring cup measurement: the error fluctuates greatly |

Pillow Packing bag type

Pillow bag (vertical, horizontal).

a Vertical seam lap bag (with pleats or no folds on the side), the vertical seam is a lap seal, and the inner and outer layers of the bag-making material are required to be heat sealable, otherwise the sealing seam is not strong;

b Longitudinal butt joint bags (with or without pleats on the sides);

c Longitudinal seam butt wrap bags.

The longitudinal seams of b and c are butt joints, the sealing is firm, and the inner layer of the packaging material has heat sealability to meet the requirements, and it is widely used.

Working principle of different packaging machines

Schematic diagram of the process of the vertical packaging machine. The packaging film is formed into a cylindrical shape by the shaper 2 and the longitudinal sealer 4. It is fed by the feeding tube 1 and is pulled downward by the film belt 5 using friction, using a horizontal sealer. 6 Seal from both sides and cut with a cutting knife 7. The hot cover of the horizontal sealer has zigzag waves. The waves should be engaged with each other to obtain a good sealing effect. The cutting knife 7 is in the middle of the horizontal sealer 6. The seal is divided into two, the top of one bag is sealed and the bottom of the other bag is sealed, thereby forming a pillow-shaped package 8 in which the longitudinal seam overlaps the seals at both ends 8.

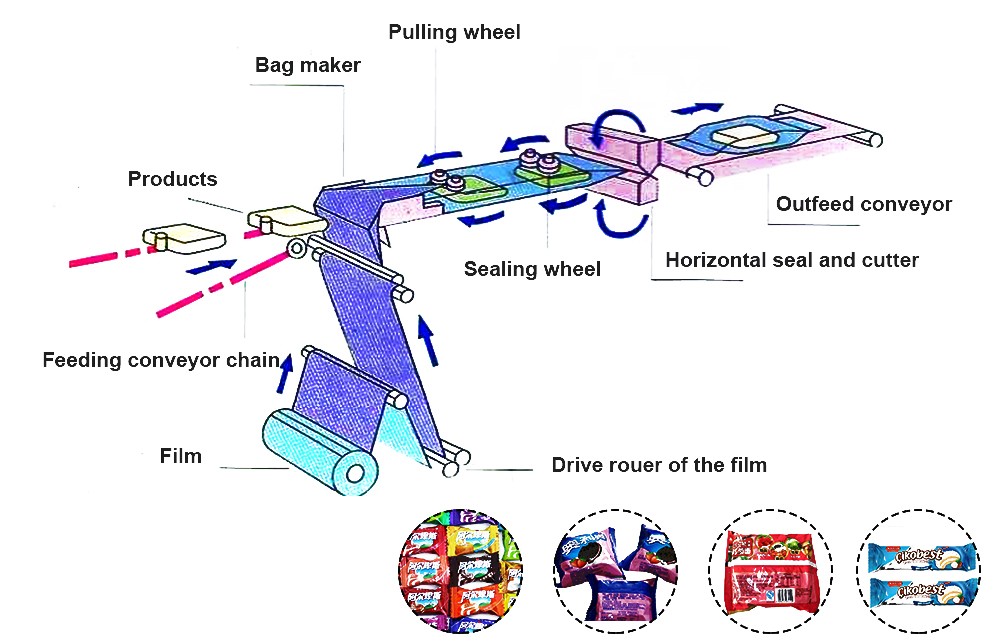

Scope of application: automatic packaging of biscuits, instant noodles, etc.

Performance: It integrates automatic packaging items, sealing and cutting in one

Packaging materials: plastic or composite materials, using reel-type film feeding

Work flow: From driver roller of the film, into former through the guidance of film, under the action of former, film naturally forms the form of roll wrap. At the same time, the to-be-packaged product is fed into the space of 1 roll of packages by the supply conveyor chain. The package film runs forward under the action of pulling roller and is longitudinally sealed and heat-sealed by sealing wheel. product Synchronous operation with the film. The package products is cut by horizontal seal and cutter sealing afterwards to form a finished package, which is output by outfeed conveyor. Because its packaging form is pillow-shaped, it becomes pillow-type wrapping or mid-seam packaging.

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines