- Shandong Loyal Industrial Co.,Ltd.

- Industrial Microwave Oven Food Extruder Machine Biscuit Making Machine

Home> Company News> Industrial Spaghetti Making Machine

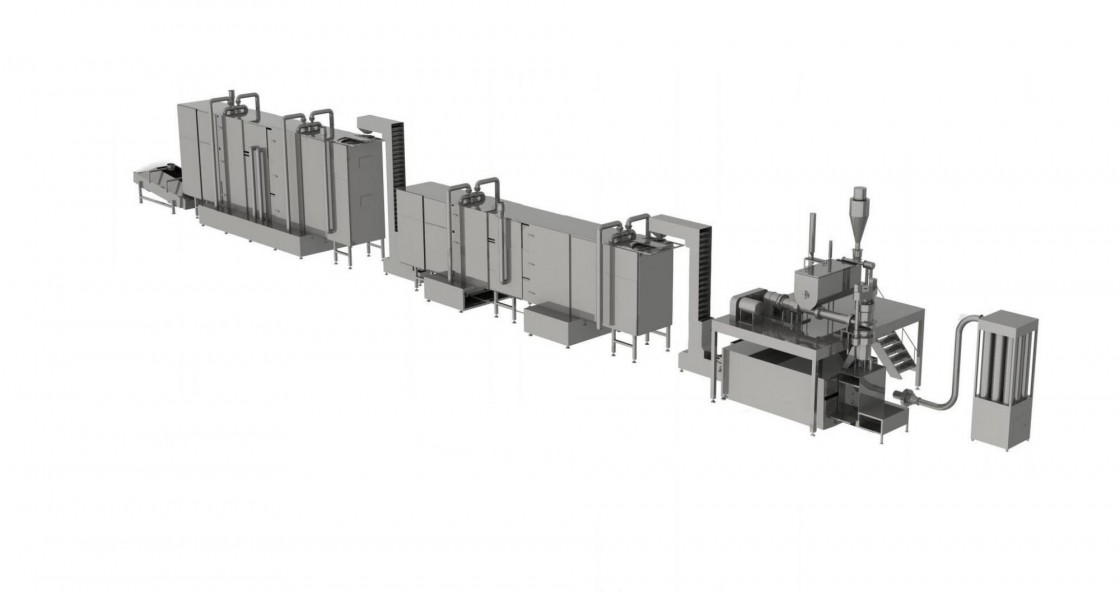

Industrial Spaghetti Making Machine

2023-06-16 11:32:02Industrial spaghetti makers are large pieces of equipment used in food processing plants or commercial kitchens to automatically produce spaghetti. The machine usually consists of dough mixer, extruder, cutter and drying system. The process starts with mixing flour, water and other ingredients in a mixing chamber to create pasta dough. The dough is then extruded through molds, which shape it into thin spaghetti. A cutting machine then trims the noodles to the desired length and separates them from each other. Once cut, freshly made spaghetti is usually transferred to a drying system that uses heat and controlled airflow to remove moisture from the pasta. Once completely dry, the spaghetti can be stored, packaged or further processed, depending on the specific requirements of the manufacturer or operator. Industrial spaghetti making machines are designed to efficiently produce large quantities of spaghetti, saving time and labor compared to manual production. They are commonly used in pasta factories, catering establishments and large food production facilities.

The Flow Chart Of Spaghetti Process Line

- Mixer à 2. Screw Conveyor à 3. Single Screw Extruder With Cooling System à 4. Pulling And Cutting Machine à 5. Hoister à 6. Drying Machine à 7. Cooling Conveyor

The Function Of Spaghetti Process Line

The main function of a spaghetti production line is to produce spaghetti efficiently and consistently on a large scale.

A production line usually consists of several steps:

- Mixing Of Ingredients: The line starts with the accurate mixing of ingredients to make pasta dough. This step may involve mixing flour, water, and other ingredients in precise proportions to achieve the desired texture and flavor of the pasta.

- Dough Extrusion: Then the mixed dough is fed into the extruder. The extruder uses pressure to force the dough through a die or set of dies, shaping it into the desired spaghetti shape and size. Extruders may have different dies to produce spaghetti of different thicknesses and shapes.

- Cutting And Shaping: Once the dough is extruded into long strips of spaghetti, it needs to be cut into individual noodle lengths. This can be done using a cutting machine or a series of blades capable of cutting the dough to the exact desired size.

- Drying: Convey the freshly cut spaghetti to the drying system. The system typically includes a series of conveyor belts or drying racks where the noodles are exposed to controlled temperature and airflow to remove moisture. Proper drying ensures that noodles are shelf stable and can be stored for longer periods of time.

- Packaging: Pack and seal the dried spaghetti in bags, boxes, trays and other forms. Packaging machines are used to efficiently weigh, fill and seal spaghetti packages. Labels or stickers with product information and branding can also be applied during the process.

- Quality Control: Throughout the production line, quality control measures are in place to ensure that the spaghetti meets the required standards. These may include visual inspections, gravimetric checks and laboratory test sampling.

By using a spaghetti production line, manufacturers can increase production efficiency, reduce manual labor, maintain consistent quality, and meet the needs of mass production. This helps ensure high-quality spaghetti is produced in a cost-effective and time-efficient manner.

Parameter Of Pasta Production Line

|

Model Parameter |

LY 3000 |

|

|

Voltage |

380 V/50Hz,3 phase |

|

|

Instant Power |

150kw |

55kw |

|

Actual power consumption |

120 kw |

35kw |

|

Certification |

CE,IBV,ISO |

|

|

Capacity |

80-120 kg/h |

|

|

Diameter |

23000 X 1500 X 2600 mm |

|

|

Worker |

Macarini: 1-2 |

|

|

This pasta food making machine line can use wheat flour as main material to make different shapes pasta , like tube , elbow , screw , shell etc . If you want more big capacity, such as 200kg/h, we can customed according to your requirement. |

||

Advantages Of Spaghetti Process Line

|

Improve Production Efficiency |

The spaghetti production line can realize the automation of each step, thereby increasing the production rate. The line can handle large quantities of dough, extrude it quickly and cut it into spaghetti. This results in increased yield and reduced production time. |

|

Consistent Quality |

By using a production line, manufacturers can ensure consistent product quality. The automated process ensures that every noodle produced is of the same size, shape and texture and meets specific quality standards. This consistency is critical to customer satisfaction and maintaining your brand's reputation. |

|

Reduce Labor Costs |

Adopting a spaghetti production line can reduce the need for manual labor. Automation replaces repetitive tasks such as mixing, extruding, cutting and packaging, minimizing the number of workers required. This not only reduces labor costs, but also reduces the risk of human error. |

|

Improved Food Safety |

The production line is designed to maintain optimum hygiene during production. Using a closed system minimizes the risk of contamination and ensures food safety. Additionally, production lines often have built-in cleaning mechanisms that make it easier to clean and sanitize equipment between batches. |

|

Improved Scalability |

The spaghetti production line is designed to handle high volume production. As the demand for spaghetti increases, the capacity of the production line can be adjusted accordingly, allowing efficient expansion without major disruptions to production. |

|

Cost Savings |

By simplifying the pasta production process, the production line can reduce overall costs. Reduced labor requirements, increased production efficiency, and improved quality control all contribute to cost savings in the long run. In addition, production lines often have energy-saving features that further reduce operating costs. |

|

Flexibility And Customizability |

The spaghetti production line can be customized to produce different types of spaghetti, such as different thicknesses or shapes. This enables manufacturers to offer a greater variety of products to meet specific market needs and customer preferences. |

Raw Material Of High Quality Pasta Making Machine

Adopts potato starch, corn starch, cassava starch, wheat flour, corn flour etc as raw materials.

Voltageof Industrial Macarons Making Machine

In China: Three phases: 380V/50Hz, Single phase: 220V/50Hz. We can make it according to customers' Local voltage according to different countries.

Spaghetti Samples

Instant Pasta Production Line

Instant Pasta Production Line 150Kw Fully Automatic Industrial Continuous Microwave Shrimp Drying Machine

150Kw Fully Automatic Industrial Continuous Microwave Shrimp Drying Machine Continuous Tunnel Honeysuckle Flower Drying Dehydrator Machine Tunnel Microwave Baking And Sterilizing Equipment

Continuous Tunnel Honeysuckle Flower Drying Dehydrator Machine Tunnel Microwave Baking And Sterilizing Equipment Automatic Microwave Frozen Meat Beef Thawing Machine

Automatic Microwave Frozen Meat Beef Thawing Machine