- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Company News> Everything you need to know about breakfast cereal extruder In 2024

Everything you need to know about breakfast cereal extruder In 2024

2024-04-20 15:49:07Introduction

In the dynamic landscape of food processing machinery, the breakfast cereal extruder stands out as a cornerstone technology in the production of breakfast cereals. As we navigate through the complexities of industrial food manufacturing in 2024, understanding the intricacies of breakfast cereal extruders becomes paramount. This guide aims to provide comprehensive insights into the workings, applications, and future prospects of breakfast cereal extruders, shedding light on their pivotal role in the food industry.

In recent years, breakfast cereal extruders have undergone significant advancements, driven by a combination of technological innovation and consumer demand. Manufacturers have introduced new features and capabilities to enhance efficiency, flexibility, and product quality. Automated controls, precise temperature regulation, and customizable settings have become standard features, allowing producers to optimize their processes and meet the diverse preferences of modern consumers.

As we venture into 2024 and beyond, breakfast cereal extruders are poised to play an even more pivotal role in the food industry. With consumers increasingly seeking nutritious, convenient, and innovative breakfast options, the demand for extruded cereals is expected to rise. Technological developments will continue to push the boundaries of what is possible, enabling manufacturers to create novel cereal products that cater to evolving tastes and lifestyles.

In the following sections of this guide, we will delve deeper into the workings of breakfast cereal extruders, exploring their types, processing techniques, quality control measures, and future trends. By the end of this comprehensive overview, readers will gain a thorough understanding of breakfast cereal extruders and their significance in the ever-changing landscape of food production.

Importance in the Food Processing Industry

Efficiency and Productivity: Breakfast cereal extruders play a pivotal role in enhancing the efficiency and productivity of breakfast cereal production. These machines are capable of high-speed processing, allowing manufacturers to meet the demands of a large-scale production while maintaining consistency in product quality.

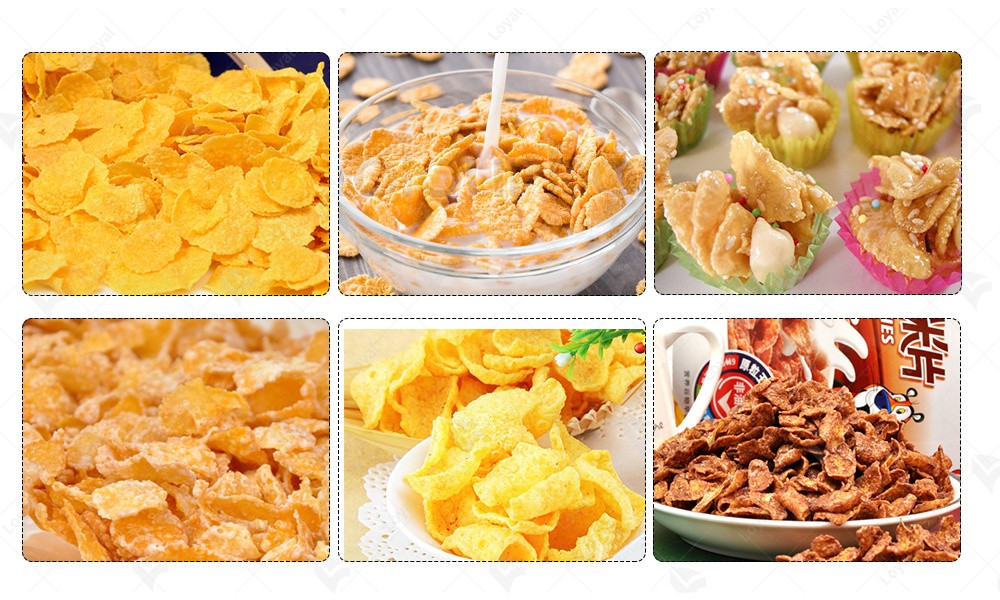

Versatility and Innovation: The versatility of breakfast cereal extruders enables manufacturers to produce a diverse range of breakfast cereal products, including flakes, puffs, loops, and shapes. This flexibility fosters innovation in product development, allowing for the introduction of new flavors, textures, and nutritional profiles to cater to evolving consumer preferences.

Quality Control: Breakfast cereal extruders facilitate precise control over the extrusion process, ensuring uniformity in product texture, flavor, and appearance. Manufacturers can adjust various parameters such as temperature, pressure, and moisture content to optimize product quality and consistency.

Cost-effectiveness: By streamlining the production process and minimizing wastage, breakfast cereal extruders contribute to cost-effectiveness in manufacturing operations. The efficient use of raw materials and energy translates into higher production yields and lower production costs per unit.

Advantages of Breakfast Cereal Extruder

Breakfast cereal extruders are at the forefront of modern food processing technology, offering numerous advantages that have revolutionized the breakfast cereal industry. Below are some key benefits of utilizing breakfast cereal extruders in 2024:

1. Versatility and Flexibility:

Breakfast cereal extruders are incredibly versatile machines capable of producing a wide variety of cereal products, including flakes, puffs, shapes, and granola clusters. Manufacturers can easily adjust the settings and parameters of the extruder to create different textures, shapes, and flavors, catering to diverse consumer preferences and market demands.

2. High Efficiency and Productivity:

One of the most significant advantages of breakfast cereal extruders is their high level of efficiency and productivity. These machines can produce large volumes of breakfast cereals in a relatively short amount of time, making them ideal for mass production. With automated processes and precise control over variables such as temperature, pressure, and moisture content, extruders ensure consistent quality and uniformity in the final products.

3. Cost-Effectiveness:

Breakfast cereal extruders offer cost-effective solutions for breakfast cereal manufacturers. By streamlining production processes and minimizing the need for manual labor, extruders help reduce operational costs and increase profitability. Additionally, their high throughput rates and efficient use of raw materials contribute to overall cost savings in the production chain.

4. Nutritional Enhancement:

Extrusion technology enables the incorporation of various ingredients into breakfast cereals, allowing manufacturers to enhance their nutritional profiles. Fortification with vitamins, minerals, fibers, and proteins is easily achievable during the extrusion process, resulting in healthier and more nutritious breakfast cereal options for consumers.

5. Product Consistency and Quality Control:

Consistency and quality control are paramount in the breakfast cereal industry, and extrusion technology excels in this regard. Breakfast cereal extruders ensure uniformity in product size, shape, texture, and taste, meeting the stringent quality standards expected by consumers. With advanced monitoring and control systems, manufacturers can maintain precise control over the entire production process, minimizing variations and defects.

6. Innovation and Customization:

Breakfast cereal extruders drive innovation and customization in the industry, enabling manufacturers to introduce new and unique cereal products to the market. From innovative shapes and textures to novel flavor combinations, extrusion technology facilitates endless possibilities for product development and differentiation, keeping consumers engaged and interested.

In conclusion, breakfast cereal extruders offer a myriad of advantages that position them as indispensable assets in the breakfast cereal manufacturing industry. From versatility and efficiency to cost-effectiveness and nutritional enhancement, these machines play a pivotal role in meeting consumer demands and driving innovation in the ever-evolving world of breakfast cereals.

Key components of extruder

|

Component |

Description |

|

Barrel |

The barrel is the main body of the extruder, typically made of stainless steel. It houses the screw(s) and provides the enclosure for the extrusion process. |

|

Screw(s) |

The screw(s) inside the barrel rotate(s) and convey(s) the raw materials forward while subjecting them to mechanical shear and heat. The design of the screw(s) influences mixing, cooking, and shaping of the cereal dough. |

|

Die |

The die is a specially designed plate with a hole or multiple holes through which the cereal dough is extruded. It determines the shape and size of the final cereal product. |

|

Cutter |

The cutter is positioned at the end of the die and is responsible for cutting the extruded cereal dough into desired lengths or shapes. It can be adjustable to produce different product sizes. |

|

Heater and |

The heater and cooling system control the temperature of the barrel to facilitate cooking and shaping of the |

|

Cooling System |

cereal dough. The cooling system helps to solidify the extruded product after shaping. |

|

Control Panel |

The control panel houses the interface for operating and monitoring the extruder. It allows operators to adjust parameters such as temperature, screw speed, and pressure to optimize the extrusion process. |

Different Types and Variations of Breakfast Cereal Extruders

In 2024, the breakfast cereal industry continues to witness advancements in extrusion technology, offering a variety of breakfast cereal extruders tailored to different production needs. Let's delve into the different types and variations of breakfast cereal extruders available in the market:

1. Single-Screw Extruders:

Single-screw extruders are the most common type used in breakfast cereal production. They feature a single rotating screw within a cylindrical barrel. As the ingredients pass through the barrel, they undergo mixing, cooking, and shaping, resulting in the desired cereal product. Single-screw extruders are known for their simplicity, reliability, and cost-effectiveness.

2. Twin-Screw Extruders:

Twin-screw extruders are gaining popularity due to their versatility and ability to handle a wide range of ingredients and recipes. These extruders feature two intermeshing screws within the barrel, providing better mixing, kneading, and shearing action. Twin-screw extruders offer enhanced control over the extrusion process and are suitable for producing a variety of breakfast cereal shapes, textures, and flavors.

3. Co-Rotating and Counter-Rotating Twin-Screw Extruders:

Within the category of twin-screw extruders, there are co-rotating and counter-rotating variations. Co-rotating twin-screw extruders feature screws that rotate in the same direction, offering high throughput and efficient mixing. On the other hand, counter-rotating twin-screw extruders have screws that rotate in opposite directions, providing enhanced self-cleaning and processing of shear-sensitive ingredients.

4. Multi-Function Extruders:

Multi-function extruders are designed to perform multiple processing steps within a single machine. These versatile extruders can handle tasks such as mixing, cooking, shaping, and coating in a continuous process. By integrating multiple functions into one unit, multi-function extruders offer increased efficiency, reduced footprint, and simplified production lines.

5. Laboratory-Scale and Pilot-Scale Extruders:

For research and development purposes, laboratory-scale and pilot-scale extruders are available. These smaller-scale extruders allow manufacturers to test new recipes, formulations, and processing parameters before scaling up to full production. Laboratory-scale extruders offer flexibility and precision for optimizing product formulations and processes.

Application and Product Innovation

In the dynamic landscape of food processing machinery, breakfast cereal extruders play a pivotal role in shaping the breakfast cereal industry. As we navigate through 2024, it's essential to explore the diverse applications and innovative products enabled by these extrusion machines.

1. Diverse Product Portfolio:

- Breakfast cereal extruders are versatile machines capable of producing a wide array of breakfast cereal products. From classic flakes and puffs to innovative shapes and textures, the possibilities are endless.

- Manufacturers leverage the flexibility of extrusion technology to create unique cereal blends, incorporating grains, fruits, nuts, and flavorings to cater to evolving consumer preferences.

2. Health and Wellness Trends:

- In response to growing health consciousness among consumers, breakfast cereal manufacturers are innovating to offer healthier options. Breakfast cereal extruders enable the incorporation of nutritious ingredients such as whole grains, fiber, protein, and vitamins into cereal formulations.

- Additionally, there is a rising demand for gluten-free, organic, and non-GMO breakfast cereals, driving manufacturers to adapt their extrusion processes and formulations accordingly.

3. Snackification of Breakfast Cereals:

- Breakfast cereals are no longer confined to breakfast tables but have emerged as popular snack options throughout the day. Extruded cereal products like granola bars, cereal clusters, and bite-sized snacks are gaining traction among consumers seeking convenient, on-the-go options.

- Breakfast cereal extruders facilitate the production of these snackified cereal products by offering precise control over texture, shape, and flavor.

4. Functional and Fortified Cereals:

- With an increased emphasis on functional foods, breakfast cereal manufacturers are incorporating functional ingredients such as probiotics, antioxidants, and omega-3 fatty acids into their products.

- Breakfast cereal extruders enable the uniform dispersion of these functional ingredients throughout the cereal matrix, ensuring consistent delivery of health benefits to consumers.

5. Customization and Personalization:

- Consumer demand for personalized products continues to drive innovation in the breakfast cereal industry. Breakfast cereal extruders equipped with advanced control systems allow manufacturers to tailor cereal products to specific demographics, tastes, and dietary preferences.

- Customization features include adjustable extrusion parameters, modular die designs, and automated recipe management systems, enabling rapid product development and customization.

Quality Assurance and Food Safety

Ensuring the quality and safety of breakfast cereals produced by breakfast cereal extruders is paramount in the food processing industry. In this section, we will delve into the rigorous quality assurance measures and food safety protocols implemented to maintain product integrity and consumer trust.

1. Quality Assurance Measures:

Quality assurance begins with the selection of high-quality raw materials. Manufacturers carefully source grains, flours, and other ingredients to meet strict quality standards. The consistency and purity of ingredients directly impact the taste, texture, and nutritional value of the final product.

2. Process Control and Monitoring:

Breakfast cereal extrusion processes are meticulously controlled and monitored to ensure consistent product quality. Parameters such as temperature, pressure, moisture content, and screw speed are closely monitored and adjusted throughout the extrusion process. Advanced sensors and automated systems enable real-time monitoring and precise control of these parameters.

3. Hygiene and Sanitation Practices:

Maintaining cleanliness and hygiene in the production environment is essential to prevent contamination and ensure food safety. Production facilities adhere to stringent sanitation protocols, including regular cleaning and disinfection of equipment, surfaces, and production areas. Employees undergo thorough training in food safety practices to minimize the risk of cross-contamination.

4. Hazard Analysis and Critical Control Points (HACCP):

HACCP principles are widely adopted in breakfast cereal manufacturing to identify and mitigate potential hazards at critical points in the production process. Hazard analysis is conducted to assess risks associated with raw materials, equipment, processes, and personnel. Critical control points are established, and preventive measures are implemented to minimize risks and ensure product safety.

5. Regulatory Compliance:

Breakfast cereal manufacturers must comply with stringent regulatory requirements set forth by food safety authorities such as the Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA). Regulatory standards encompass various aspects of food safety, including hygiene, sanitation, labeling, and packaging. Compliance with these standards is non-negotiable and subject to regular inspections and audits.

6. Traceability and Recall Procedures:

In the event of a food safety issue or product recall, traceability is crucial for identifying and removing affected products from the market promptly. Manufacturers implement robust traceability systems to track raw materials, production batches, and distribution channels. This enables swift action to be taken to address any potential risks to consumer health and safety.

Post-Maintenance Guide for Breakfast Cereal Extruder

|

Maintenance Task |

Description |

|

Cleaning |

Cleaning is essential to remove residual material and prevent contamination. Use appropriate cleaning agents and follow manufacturer guidelines. Ensure thorough cleaning of the barrel, screw, die, and other components. Pay special attention to areas prone to buildup. |

|

Lubrication |

Lubrication is necessary to reduce friction and wear between moving parts, prolonging the life of the extruder. Use food-grade lubricants recommended by the manufacturer. Apply lubricant to bearings, gears, and other moving parts as per the maintenance schedule. |

|

Inspection |

Regular inspection helps identify potential issues before they escalate. Check for signs of wear, corrosion, or damage on all components. Verify the alignment of the screw and ensure proper functioning of seals and gaskets. |

|

Calibration |

Calibration ensures the extruder operates at the desired parameters for optimal performance. Check and adjust temperature, pressure, and screw speed settings as needed. Verify the accuracy of sensors and controllers. |

|

Parts Replacement |

Replace worn or damaged parts promptly to prevent breakdowns and maintain efficiency. Keep spare parts on hand for quick replacement. Follow manufacturer recommendations for part replacement intervals. |

Reference

1. Food Processing:

- Website: [Food Processing](https://www.foodprocessing.com/)

2. Food Engineering:

- Website: [Food Engineering](https://www.foodengineeringmag.com/)

3. Process Industry Forum:

- Website: [Process Industry Forum](https://www.processindustryforum.com/)

4. Food Manufacture:

- Website: [Food Manufacture](https://www.foodmanufacture.co.uk/)

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines