- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Company News> Everything you need to know about puff snack extruder In 2024

Everything you need to know about puff snack extruder In 2024

2024-04-24 15:43:23Introduction to Puff Snack Extruder

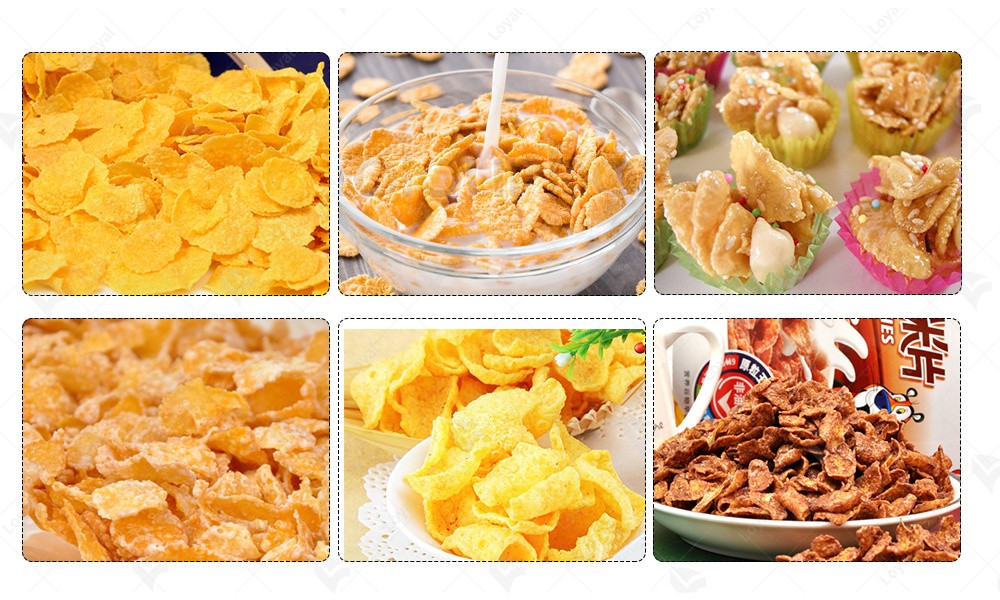

Puff snack extruders represent a cornerstone of modern snack production, revolutionizing the way popular snacks are manufactured. These sophisticated machines utilize advanced extrusion technology to transform raw ingredients into delightful puffed snacks enjoyed by millions worldwide.

The puff snack extruder operates on a simple yet ingenious principle: the combination of heat, pressure, and mechanical force. Raw ingredients such as grains, starches, and flavorings are fed into the extruder's chamber, where they undergo a precise cooking and shaping process. As the mixture passes through the extrusion die, it is subjected to high temperature and pressure, causing it to expand rapidly and form the characteristic airy texture of puff snacks.

In 2024, puff snack extruders have evolved to incorporate state-of-the-art features and technologies, enabling manufacturers to produce a diverse range of snack shapes, sizes, and flavors with unparalleled efficiency and consistency. From classic cheese puffs to innovative multigrain snacks, the versatility of puff snack extruders continues to drive innovation in the snack industry, meeting the ever-changing demands of consumers for delicious, wholesome snacks.

Technological Innovation

In 2024, technological innovation in the realm of puff snack extruders has reached unprecedented heights, revolutionizing the landscape of snack production. Puff snack extruders, the backbone of modern snack manufacturing, have undergone significant advancements to meet the evolving demands of consumers and industry standards.

Advanced Features and Customization Options

The latest generation of puff snack extruders boasts advanced features and customization options that cater to the diverse needs of snack manufacturers. These extruders are equipped with precision control systems that allow for fine-tuning of parameters such as temperature, pressure, and moisture content. This level of control ensures consistent product quality and texture, meeting the stringent requirements of snack producers and discerning consumers alike.

Automation and Efficiency Enhancements

Automation has become a cornerstone of puff snack extrusion technology, streamlining production processes and maximizing efficiency. Modern extruders are equipped with automated feeding systems, continuous mixing mechanisms, and integrated sensors that monitor production in real-time. This automation reduces the need for manual intervention, minimizing human error and increasing throughput rates. As a result, manufacturers can produce larger volumes of puff snacks in shorter timeframes, meeting the demands of today's fast-paced market.

Material Innovation and Sustainability Focus

In response to growing concerns about sustainability, manufacturers of puff snack extruders have placed a greater emphasis on material innovation and eco-friendly practices. Extruder components are now constructed from durable, food-grade materials that ensure longevity and food safety. Additionally, there is a growing trend towards the use of biodegradable and recyclable materials in extrusion processes, reducing environmental impact and promoting a circular economy.

Integration of IoT and Data Analytics

The integration of Internet of Things (IoT) technology and data analytics has further enhanced the capabilities of puff snack extruders. Sensors embedded within the extrusion equipment collect data on process parameters and performance metrics in real-time. This data is then analyzed using advanced analytics algorithms to optimize production efficiency, predict maintenance needs, and identify areas for improvement. By harnessing the power of data, manufacturers can make informed decisions that drive continuous innovation and process optimization.

Advantages of Puff Snack Extruder

Puff snack extruders offer numerous advantages in the snack production industry. Below is a concise overview of some of the key benefits of using puff snack extruders:

|

Advantage |

Description |

|

Versatility |

Puff snack extruders can produce a wide variety of snack products, including cheese puffs, corn curls, and flavored snacks. |

|

Efficiency |

These extruders operate at high speeds, allowing for large-scale production with minimal downtime. |

|

Customization Options |

Manufacturers can easily adjust the extrusion process to create snacks with different shapes, sizes, textures, and flavors to meet consumer preferences. |

|

Product Consistency |

Puff snack extruders ensure consistent product quality and texture, leading to satisfied customers and repeat purchases. |

|

Nutrient Retention |

The extrusion process preserves the nutritional content of ingredients, making puff snacks a healthier option compared to traditional fried snacks. |

|

Cost-Effectiveness |

Compared to traditional snack manufacturing methods, puff snack extrusion offers cost savings in terms of energy consumption, labor, and raw materials. |

|

Shelf-Life Extension |

Puff snacks produced by extruders have a longer shelf life due to their reduced moisture content and enhanced resistance to spoilage. |

|

Hygienic Production Environment |

Extrusion technology allows for a closed and controlled production environment, minimizing the risk of contamination and ensuring food safety. |

|

Reduced Environmental Impact |

Puff snack extrusion consumes less energy and generates fewer waste by-products compared to frying or baking processes, contributing to environmental sustainability. |

In summary, puff snack extruders offer a versatile, efficient, and customizable solution for snack production, while also maintaining product consistency, nutritional integrity, and cost-effectiveness. Additionally, they contribute to extended shelf life, hygienic production practices, and reduced environmental impact, making them a preferred choice for snack manufacturers in 2024 and beyond.

Maintenance and Troubleshooting

Maintenance:

Regular maintenance is essential to keep the puff snack extruder running efficiently. Here are some key maintenance tasks:

1. Cleaning: Regular cleaning of the extruder components, including the barrel, screws, and die, is crucial to prevent buildup of residue or contaminants. Use appropriate cleaning agents and procedures recommended by the manufacturer.

2. Lubrication: Lubricate the moving parts of the extruder, such as bearings and gears, according to the manufacturer's specifications. Proper lubrication reduces friction and wear, prolonging the life of the equipment.

3. Inspections: Conduct routine inspections of the extruder components to check for signs of wear, damage, or corrosion. Replace any worn or damaged parts promptly to prevent further deterioration and potential breakdowns.

Troubleshooting:

Despite regular maintenance, puff snack extruders may encounter issues during operation. Here are some common troubleshooting steps:

1. Blockages: If the extruder becomes blocked, causing a decrease in output or irregular product shapes, stop the machine immediately and clear the blockage. Check for foreign objects or excessive buildup of material inside the barrel and remove them carefully.

2. Temperature Fluctuations: Variations in temperature can affect the quality and consistency of the extruded snacks. Monitor temperature sensors regularly and adjust heating or cooling settings as needed to maintain consistent operating temperatures.

3. Product Quality Issues: If the quality of the extruded snacks is not meeting specifications, investigate potential causes such as changes in ingredient composition, die design, or processing parameters. Make adjustments accordingly to achieve the desired product characteristics.

Quality Control and Safety Measures

Quality control and safety measures are paramount considerations in the operation of puff snack extruders in 2024. Maintaining strict adherence to these standards ensures the production of safe, high-quality snack products that meet consumer expectations.

Process Parameter Monitoring

To uphold quality standards, it is imperative to monitor key process parameters throughout the extrusion process. This includes closely monitoring factors such as temperature, pressure, and moisture content. Deviations from optimal levels can result in product defects or safety hazards. Automated monitoring systems equipped with sensors and alarms help detect and address such deviations in real-time, minimizing the risk of product non-conformities.

Product Testing and Analysis

Regular product testing and analysis are essential components of quality control in puff snack extrusion operations. Samples should be periodically collected and subjected to comprehensive testing to ensure consistency in product attributes such as texture, flavor, and nutritional content. Additionally, microbial testing is crucial to verify the absence of harmful pathogens and contaminants, safeguarding consumer health and safety.

Equipment Maintenance and Calibration

Proper maintenance and calibration of puff snack extruders are vital for ensuring consistent product quality and operational safety. Regular equipment inspections, cleaning, and lubrication routines prevent mechanical failures and contamination risks. Furthermore, calibration of instrumentation and control systems maintains accuracy in process control, enabling precise adjustment of operating parameters to achieve desired product specifications.

Hygiene and Sanitation Practices

Maintaining hygienic conditions within the production facility is essential for preventing contamination and ensuring product safety. Strict adherence to sanitation protocols, including thorough cleaning of equipment and premises, minimizes the risk of microbial contamination. Personnel should also adhere to strict personal hygiene practices and wear appropriate protective gear to prevent cross-contamination during production.

Compliance with Regulatory Standards

Compliance with regulatory standards and industry guidelines is non-negotiable in puff snack extrusion operations. Food safety regulations set forth by government agencies mandate strict adherence to hygiene, sanitation, and quality control practices. Additionally, voluntary certifications such as HACCP (Hazard Analysis and Critical Control Points) provide a framework for identifying and mitigating potential hazards throughout the production process, ensuring consumer confidence in the safety and quality of the end product.

Comparison between Loyal and Clextral Companies

|

Feature |

Loyal Company |

Clextral Company |

|

Technological Leadership |

Offers advanced technological solutions, focuses on innovation and research and development |

Built upon advanced technology, continuously driving industry advancements |

|

Product Range |

Offers diversified food processing equipment, covering multiple sectors |

Specializes in extrusion technology, providing comprehensive extrusion solutions |

|

Customer Service |

Provides comprehensive customer support and customized solutions |

Emphasizes customer needs, offering personalized services and technical support |

|

Global Influence |

Holds extensive influence and customer base in international markets |

Established strong partnerships globally |

|

Innovation and R&D |

Invests in innovation and research and development, driving product advancement |

Maintains leadership through continuous innovation and technological improvements |

|

Industry Recognition |

Widely recognized in the industry, enjoys a good reputation |

Renowned in the industry, regarded as a reliable partner |

Market Trends and Industry Outlook

As we delve into the realm of puff snack extruders in 2024, it's essential to grasp the prevailing market trends and anticipate the industry's trajectory.

In recent years, the demand for puff snack extruders has surged, driven by a growing consumer appetite for convenient and flavorful snack options. Manufacturers are increasingly turning to extrusion technology to meet this demand efficiently and economically.

One notable trend in the market is the emphasis on customization and innovation. Consumers today crave variety and novelty in their snack choices, prompting manufacturers to explore new flavors, shapes, and textures. Puff snack extruders equipped with advanced customization capabilities enable manufacturers to experiment with a wide range of ingredients and formulations, catering to ever-evolving consumer preferences.

Moreover, sustainability has emerged as a key focus area for the snack industry, driving the adoption of eco-friendly practices and materials in puff snack extrusion processes. Manufacturers are investing in energy-efficient equipment and exploring biodegradable packaging options to minimize environmental impact and meet consumer expectations for sustainable products.

In terms of industry outlook, the future appears promising for puff snack extruder manufacturers and suppliers. With advancements in technology and increasing market demand, the extrusion industry is poised for continued growth and innovation. Manufacturers who stay ahead of the curve by investing in research and development, embracing sustainability practices, and staying attuned to consumer preferences are likely to thrive in the competitive snack market landscape.

In conclusion, the market for puff snack extruders in 2024 is characterized by a focus on customization, innovation, and sustainability. Manufacturers who adapt to these trends and anticipate future developments stand to benefit from the burgeoning demand for flavorful and convenient snack options.

Environmental Sustainability Initiatives

In 2024, environmental sustainability initiatives are paramount in the operation of puff snack extruders. As manufacturers strive to minimize their environmental footprint and meet the growing demand for eco-friendly practices, several key initiatives have emerged in the industry.

Firstly, one notable initiative is the adoption of energy-efficient technologies in puff snack extruder designs. Manufacturers are increasingly investing in equipment that optimizes energy usage during the extrusion process. This includes the integration of advanced insulation materials to reduce heat loss and the implementation of energy recovery systems to capture and reuse heat generated during operation.

Secondly, there is a focus on reducing waste generation in puff snack extrusion facilities. This involves implementing strategies to minimize material losses during production and maximize the utilization of raw materials. Manufacturers are optimizing their processes to ensure efficient use of ingredients, reducing both waste and costs associated with production.

Furthermore, environmental sustainability initiatives extend to the packaging of puff snack products. Manufacturers are exploring alternative packaging materials that are biodegradable or recyclable, reducing the environmental impact of packaging waste. Additionally, efforts are being made to minimize the use of single-use plastics and adopt more sustainable packaging solutions.

Moreover, water conservation is a critical aspect of environmental sustainability in puff snack extrusion operations. Manufacturers are implementing water recycling and reuse systems to minimize water consumption and reduce the strain on local water resources. By treating and recycling process water, manufacturers can minimize their environmental impact and contribute to water conservation efforts.

Training and Skills Development

Training and skills development are essential components of mastering the operation and maintenance of a puff snack extruder in 2024. This section will outline the key aspects of training and skill development required for personnel involved in working with puff snack extruders.

Comprehensive Training Programs:

Operators and maintenance personnel should undergo comprehensive training programs tailored to the specific requirements of puff snack extrusion processes. These programs should cover:

1. Equipment Operation: Training should focus on understanding the functioning of the puff snack extruder, including its components, controls, and operating procedures. Operators should be proficient in starting up, running, and shutting down the extruder, as well as making adjustments to parameters such as temperature, pressure, and speed.

2. Maintenance Procedures: Proper maintenance is critical for ensuring the longevity and efficiency of a puff snack extruder. Training should include instruction on routine maintenance tasks such as cleaning, lubrication, and inspection of components. Personnel should also be trained in troubleshooting common issues that may arise during operation.

3. Safety Protocols: Safety should be prioritized in all aspects of working with a puff snack extruder. Training programs should emphasize the importance of following safety protocols, wearing appropriate personal protective equipment, and understanding emergency procedures in case of accidents or equipment malfunctions.

Skill Development:

In addition to formal training programs, ongoing skill development is essential for operators and maintenance personnel to stay updated with the latest advancements in puff snack extrusion technology. Key skills to develop include:

1. Problem-Solving Abilities: Personnel should be equipped with problem-solving skills to quickly identify and address issues that may arise during operation. This may involve diagnosing mechanical problems, troubleshooting equipment malfunctions, and implementing effective solutions to minimize downtime.

2. Technical Proficiency: A solid understanding of the principles of puff snack extrusion is crucial for effective operation. Personnel should be familiar with the mechanics of extrusion, the behavior of different ingredients during processing, and the factors that affect product quality and consistency.

3. Attention to Detail: Precision is key in puff snack extrusion to ensure uniformity and quality of the final product. Operators should pay close attention to process parameters and be able to make precise adjustments as needed to meet product specifications.

Reference

1. Food Processing:

Website: [Food Processing](https://www.foodprocessing.com/)

2. Food Engineering:

Website: [Food Engineering](https://www.foodengineeringmag.com/)

3. Process Industry Forum:

Website: [Process Industry Forum](https://www.processindustryforum.com/)

4. Food Manufacture:

Website: [Food Manufacture](https://www.foodmanufacture.co.uk/)

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines