- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Processing> Discover The Secret To Perfect nutrition bar production line:nutrition bar production line Recipes

Discover The Secret To Perfect nutrition bar production line:nutrition bar production line Recipes

2025-05-27 14:57:46If you want to know more story about LOYAL brand, here can help you - https://www.facebook.com/foodmachineloyal

Introduction

The global demand for nutrition bars continues to rise, driven by increasing health consciousness and the need for convenient, protein-rich snacks. Whether producing protein bars, energy bars, or meal replacements, selecting the right nutrition bar production line is crucial for maintaining product quality, efficiency, and scalability.

According to food industry expert Dr. Laura Simmons, "A well-designed production system not only ensures consistent output but also minimizes waste and operational delays." Investing in the right nutrition bar making machine requires careful evaluation of several key factors—from production capacity to hygiene standards—to ensure long-term success.

Production Capacity & Scalability

Before purchasing a nutrition bar equipment setup, manufacturers must assess their current and future output needs. Small-scale operations may benefit from compact, semi-automatic lines, while large manufacturers require fully automated nutrition bar production lines with higher throughput.

Modular designs are particularly advantageous, allowing businesses to expand capacity without replacing entire systems. For example, adding extra molding units or packaging modules can significantly increase production volume as demand grows.

Nutrition bar production line flow chart

Sugar boiled pot--- Mixer--- Cereals bar cutting machine--- Packaging machine

Nutrition bar equipment is not limited to the ones mentioned above, and other equipment can be added as needed.

For example, if you want to make a rounded arched nutrition bar, you need a mold forming machine. If the raw material has high viscosity, you need to add a refrigerator and a strip cutter. If you want coating and latte art, you need to add a coating machine and a latte art machine.

The function of nutrition bar production line

1.Sugar boiled pot: can melt sugar, stir, and boil sugar together

2.Mixer: mixing raw materials. With heat preservation effect, the inner wall is sprayed with Teflon, and the stirring shaft and stirring claws are sprayed with Teflon

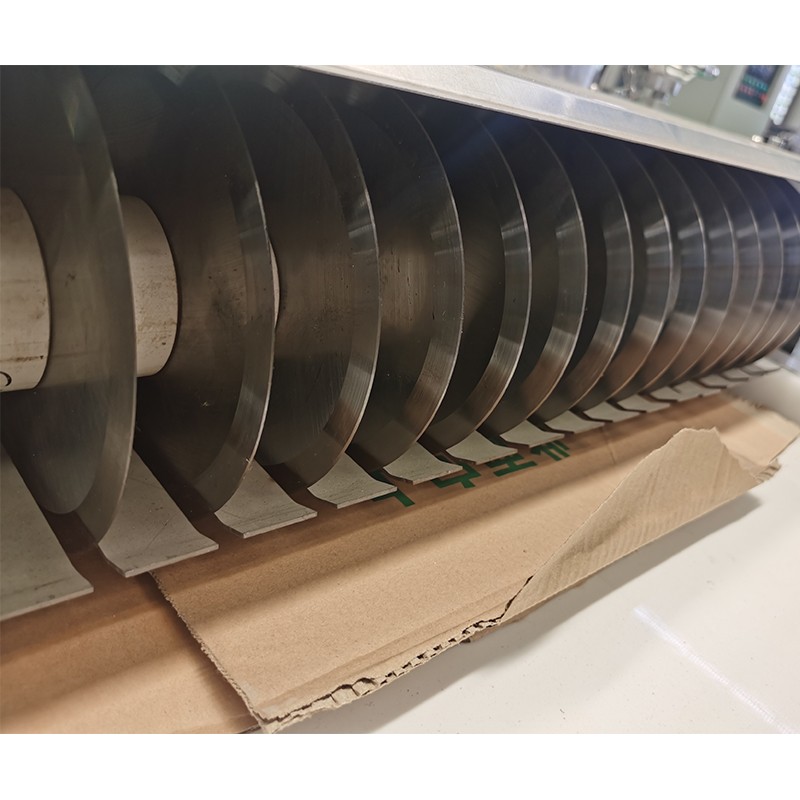

3.Cereals bar cutting machine: used for leveling, cooling, cutting and forming of products.

4.Packaging machine: finally, the dried bar is packaged in a suitable container and labeled for distribution. Packaging is an important step to ensure that the product remains fresh and free from contamination during transportation and storage.

Layout for the nutrition bar production line

Our machines can be flexibly arranged according to the size and dimensions of the factory. We can also customize the size of the machine according to the data you provide.

Sample of nutrition bar production line

Other substances and nutrients can be added as needed, such as chocolate, nuts, fruits, iron, calcium, vitamin D, etc.

How to Optimize Your Nutrition Bar Equipment for Maximum Output

Scaling production while maintaining quality is one of the biggest challenges in nutrition bar manufacturing. Whether you operate a small-batch facility or a high-volume plant, optimizing your nutrition bar production line is essential to meet demand without compromising efficiency.

According to food production specialist Dr. Elena Martinez, "The difference between a profitable operation and an underperforming one often comes down to how well the equipment is utilized." Proper workflow design, maintenance, and staff training can significantly enhance the output of your nutrition bar making machines.

Streamlined Workflow Design

An efficient layout minimizes bottlenecks and maximizes the productivity of your nutrition bar equipment. Consider these key aspects:

Linear Production Flow – Arrange mixing, molding, cooling, and packaging stations in a logical sequence to reduce unnecessary movement.

Adequate Spacing – Ensure enough room between machines for operators to work safely and perform quick adjustments.

Buffer Zones – Temporary storage areas between stages help maintain a steady workflow.

A well-planned nutrition bar production line reduces downtime and allows for smoother transitions between batches.

Preventive Maintenance Routines

Regular upkeep is crucial to avoid unexpected breakdowns in nutrition bar making machines. A structured maintenance schedule should include:

Daily Checks – Inspect belts, motors, and mixing blades for wear.

Weekly Lubrication – Ensure moving parts operate smoothly.

Monthly Deep Cleaning – Remove residue from molds, conveyors, and extruders to prevent contamination.

Proactive maintenance extends equipment lifespan and prevents costly production halts.

Staff Training & Workflow Coordination

Even the most advanced nutrition bar equipment underperforms without skilled operators. Key training focus areas include:

Machine Operation – Workers should understand settings, troubleshooting basics, and safety protocols.

Efficiency Practices – Cross-training staff reduces delays when switching between tasks.

Quality Control – Recognizing defects early prevents large-scale waste.

A well-coordinated team ensures that the nutrition bar production line runs at peak efficiency.

Optimizing a nutrition bar making machine setup requires a balance of smart workflow design, disciplined maintenance, and skilled personnel. By refining these elements, manufacturers can boost output while maintaining consistent quality—key factors in staying competitive in the growing nutrition bar market.

Ultimately, investing time in optimization today leads to greater productivity and profitability tomorrow.

Common Challenges and How to Address Them

Operating a nutrition bar production line can present various challenges that impact product quality and production efficiency. Recognizing these issues early and implementing effective solutions helps maintain smooth operations and prolong the life of your nutrition bar equipment.

One frequent issue is misalignment of machines along the production line. When mixers, forming units, or cutting machines are not precisely aligned, bars may have uneven shapes or inconsistent thickness. Regularly checking machine positioning and performing minor adjustments can prevent this problem. Precision during installation is key, but ongoing monitoring is equally important.

Feed inconsistencies are another common challenge. Uneven ingredient flow into the mixer or forming machine can cause variations in bar texture or ingredient distribution. To address this, ensure feeding systems such as conveyors or hoppers are clean and free of blockages. Adjust feed rates based on ingredient characteristics to maintain steady input.

Product inconsistencies, like bars that crumble or stick together, often stem from improper cooling or forming pressure. Monitoring temperature control within cooling tunnels and ensuring the forming machines apply uniform pressure can improve product integrity. Routine checks during production help catch these issues early.

Preventative maintenance strategies are vital to reducing downtime. Scheduled inspections, cleaning, and lubrication of moving parts keep the nutrition bar making machine operating at peak efficiency. Implementing a maintenance calendar and training staff to recognize wear signs also helps avoid unexpected breakdowns.

To extend the longevity of your nutrition bar equipment, avoid overloading machines and maintain proper operating conditions. Machines running beyond their intended capacity can experience accelerated wear or mechanical failures.

In summary, proactive troubleshooting combined with regular maintenance safeguards your nutrition bar production line from common pitfalls, ensuring consistent product quality and reliable output.

FAQs About Nutrition Bar Production Line and Equipment

Q1: What is the difference between a nutrition bar production line and a nutrition bar making machine?

A: A nutrition bar production line refers to the complete setup including all machines and equipment used from ingredient mixing to packaging. A nutrition bar making machine is a specific piece of equipment within that line responsible for tasks such as mixing, forming, or cutting.

Q2: Can nutrition bar making machines handle different ingredient types?

A: Yes, most machines are designed to work with various ingredients like nuts, grains, syrups, and powders. It’s important to verify material compatibility when selecting equipment to ensure smooth processing and product quality.

Q3: How often should nutrition bar equipment be cleaned?

A: Cleaning frequency varies based on production volume but should occur at least once per shift or during product changeovers. Regular cleaning prevents contamination and maintains hygiene standards.

Q4: What kind of maintenance is needed for nutrition bar making machines?

A: Routine maintenance includes cleaning, lubrication of moving parts, inspection of belts and gears, and checking alignment. Preventative maintenance schedules help reduce breakdowns and extend equipment lifespan.

Q5: Is special training required to operate nutrition bar production equipment?

A: Yes, operators should receive training on machine functions, safety protocols, maintenance procedures, and quality control measures to ensure efficient and safe production.

Q6: How can I ensure consistent product quality in my nutrition bar production?

A: Consistency relies on precise ingredient preparation, proper machine calibration, routine quality checks, and adherence to operating guidelines.

If the above introduction makes you interested in the nutritional bar production line and want to find a supplier, I will introduce it to you next.

Recommended Company

Shandong Loyal Industrial Co.,Ltd. Is a Manufacturer Of Snacks Extruder Machine , Industrial Microwave Oven , Corn Flakes Production Line , And a Standing Director Of China Food And Drying Equipment Industry Association.

The Self-developed Twin-screw Extruder And Single-screw Equipment of Shandong Loyal Machinery Have Been Used In Production: Puffed Snack Food, Breakfast Cereal Corn Flakes, Fried Pasta, Bread Crumbs, Fruit Chips, Baby Food, Textured Soy Protein (tsp) Food, Fish Feed And Pet Food. a Variety of Snack Production Line Supporting Products.at The Same Time, The Batching, Drying, Flaking, Baking, Frying And Spraying Equipment Matching The Twin-screw Extrusion System Have All Achieved Independent Design And Production.

Our Extrusion System Is Widely Used In: Puffed Snack Foods, Breakfast Cereals, Vegetable Protein Meat Products, Soy Based Nutrition Bars, Reconstituted Rice, Grain Nutrition Powder, Modified Starch, Starch-based Sticky Music Children's Educational Toys, Degradable Starch-based Packaging Filling Materials, Bread Crumbs And Other Food Additives, Pet Food, Aquatic Feed, Biology And Chemical Industries.

Customer-specific Food Processing Plant Project Solutions

As one of the leading manufacturers of food processing equipment, we are always searching for new solutions that benefit our snack food customers. Our experienced frying engineers always find the optimal solution for your industrial batch and continuous frying system line application. That's why we also develop, design and produce custom fried snack production line.

Close collaboration with our customer is important to us even in the early development phase. No matter what the special requirements of instant noodles production line, snack food extruder machine, pasta production line application, we can develop a custom made food processing equipment to match your needs.

Loyal have a unique and efficient industrial continuous frying equipment for snack food extruder machine that provides the right crunch and desired moisture level.

The Industrial Microwave Sterilization Defrosting Drying Machine can be designed as a dry powder dosing system and a wet slurry dosing system as required.

Some snacks can also be fried according to taste requirements, and we also provide Fried Snack Production Line for the processing and packaging of fried extruded snacks.

Loyal Food Production Line meet the needs of customers to obtain snack food that meet the needs.

In ovens or drying units, electric or gas can be used as heating sources.

Loyal have a unique and efficient industrial continuous frying equipment for snack food extruder machine that provides the right crunch and desired moisture level.

The Industrial Microwave Sterilization Defrosting Drying Machine can be designed as a dry powder dosing system and a wet slurry dosing system as required.

Some snacks can also be fried according to taste requirements, and we also provide Fried Snack Production Line for the processing and packaging of fried extruded snacks.

About packaging and after-sales service

Packing: Plastic Film Suitable For Ocean Carriage

Technical Support: The customer can inform machine related problems to us via telephone, email or fax. All information will be recorded and will be reported to the After-sale Service team. Meanwhile, the sales person will be tracking the case until problem solved.

Service Team: We have a professional After-sale Service team including10 professional engineers with at least 6 years working experience. They can handle technical consultation about manufacturing process, maintenance, fault diagnosis and troubleshooting, etc.

After-sale Service available :1.Check & test before delivery 2.Instruction for installation 3.On site commissioning 4.Repair & maintenance

After the receipt the advanced payment, we will provide allocation chart at the buyer’s request. When effect the shipment, we’ll provide operation manual, etc. in English.

Reference

The following are five authoritative foreign literature websites in the field of Industrial food machinery:

1. Food Engineering Magazine

Website: https://www.foodengineeringmag.com/

2.Food Processing Magazine

Website: https://www.foodprocessing.com/

3.Journal of Food Engineering

Website:https://www.journals.elsevier.com/journal-of-food-engineering

4. Food Manufacturing Magazine

Website:https://www.foodmanufacturing.com/

5. International Journal of Food Science & Technology

Website:https://onlinelibrary.wiley.com/

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines