- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Processing> How Does The Vegetarian Meat Food Extrusion Line Work?

How Does The Vegetarian Meat Food Extrusion Line Work?

2020-10-26 12:01:53Kurkure food is a special squeezed food that is very crunchy in your mouth. The corn grits are mixed with a certain proportion of water and then enter the food extruder. Under the squeezing and kneading action of the two turntables of the Twin screw extruder, the corn grits form irregular twisted shapes, and then the cutting knife cuts them into the required The length of the product.

Nowadays, vegetarian meat has entered the daily life of the general public. Many restaurants have "meat dishes" such as vegetarian abalone and vegetarian chicken. There are also many vegetarian meals such as pixel sausages, vegetarian burgers, and vegetarian bacon in Western food. In the snack food industry, vegetarian meat also occupies a place. Next, Shandong Loyal will talk to you about the development status of vegetarian meat and the technical equipment involved in its production. So that everyone can understand more about vegetarian meat.

Vegetarian meat refers to the vegetarian food with the flavor and texture similar to real meat. Generally, plant protein is used as the main raw material and is made through modern processing techniques such as extrusion, steaming, and molding. At present, vegetarian meat products include vegetarian meat pieces, vegetarian meatballs, vegetarian ham sausages, etc. With the rapid development of technology, many innovative vegetarian meat products emerge in endlessly.

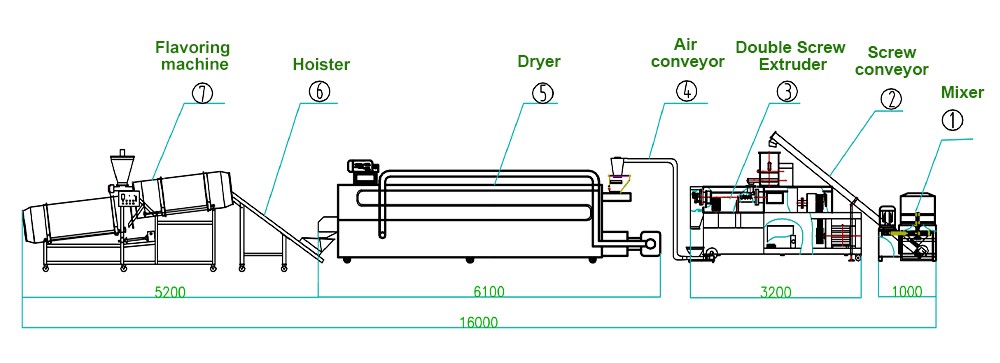

The soybean protein production line usually includes steps such as crushing, extrusion, preparation, and drying. Among the existing vegetarian meat foods, protein vegetarian meat is our most common category. The raw material for protein meat is soy protein. First, the raw materials are ground into powder by a pulverizer to lay the foundation for the subsequent preparation process. Modulation is to mix the previously crushed soy flour with salt, water and other materials, and the manufacturer will modulate it into different flavors according to its own formula.

After the preparation and mixing, extrusion is carried out. This step is the key to whether the finished product has real meat structure and taste. Put the mixed materials into the extruder for pressure and heating. Let the material be shaped, and in order to achieve a high-quality molding appearance and a delicate and tight taste, it is necessary to start with temperature and pressure. If the temperature and pressure are not well controlled, the cooked protein meat is prone to char, raw, broken, broken, etc. The automatic and controllable functions of the extrusion machine applied in the processing procedure can quickly and conveniently avoid the occurrence of problems.

Fully automatic temperature control system is a feature of most extrusion machines. The temperature during processing can be precisely controlled. Let food be produced in the right environment. In addition, today's extrusion presses mostly use computer programs. In addition to temperature, pressure can also be parameterized. And extrusion is convenient for operation and makes product quality easier to control.

Soya Nuggets Making Machine

Soya Nuggets Making Machine Soya Badi Making Machine

Soya Badi Making Machine Soya Chunks Manufacturing Machine

Soya Chunks Manufacturing Machine Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines