- Shandong Loyal Industrial Co.,Ltd.

- Industrial Microwave Oven Food Extruder Machine Biscuit Making Machine

Home>Products>Industrial Microwave Oven>Industrial Continuous Belt Microwave Dehydrator Mealworm Drying Machine

Industrial Continuous Belt Microwave Dehydrator Mealworm Drying Machine

Loyal Industrial Continuous Belt Microwave Dehydrator Mealworm Drying Machine has a number of Mealworm Microwave Tunnel Drying Machine project technology patents, which can provide you with the most detailed formula and process documents, which can save Mealworm Microwave Tunnel Drying Machine costs while improving Good development in the Industrial Continuous Belt Microwave Dehydrator Mealworm Drying Machine industry makes your Mealworm Microwave Tunnel Drying Machine project profitable in the Mealworm Drying Machine industry.

- Microwave Dehydrator Mealworm Drying Machine

- Mealworm Drying Machine

- China

- CE,ISO9001,SGS ,BV

- 1Set of Microwave Dehydrator Mealworm Drying Machine

- Negotiation

- Wooden case or wooden pellets depended on clients' requirement

- 20days--35days

- L/C,D/P,Western Union,MoneyGram,T/T

- 20days/Microwave Dehydrator Mealworm Drying Machine

Industrial Continuous Belt Microwave Dehydrator Mealworm Drying Machine Description

Insect and Bug microwave drying oven

Black soldier fly larvae industrial microwave dryer has reasonable price, reliable quality and professional service! Our company provides customers full set service. Cost accounting, dryer design, raw material recipes, machine installation and debugging, design molds according to customer requirements.

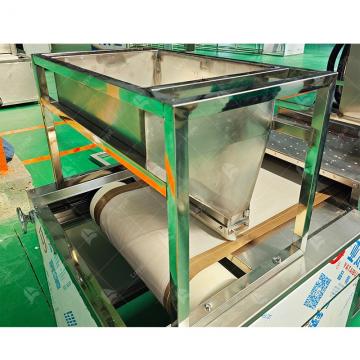

Mealworm microwave drying machine, this type of equipment belongs to the Insect and Bug microwave drying oven specially used for black soldier flies, mealworm, silkworm chrysalis, fly maggots, grasshoppers and other insects. The Microwave insect dryer adopts fully automatic assembly line drying, and the feeding adopts hopper type feeding. Free on-site production operations are provided, and one-stop technical solutions are provided in combination with user products.

What Are The Advantages Of Insect And Bug Microwave Drying Oven?

Because the overall radiation heating method of the microwave directly acts on each black soldier fly molecule, the drying is uniform, and the black soldier fly can be dried within a few minutes. In addition, due to the "water-loving" characteristics of microwaves, black soldier flies with more water content absorb more microwave energy than those with low water content. In addition, the electromagnetic field uniformity of black soldier fly larvae industrial microwave dryer is optimized to ensure excellent uniformity of microwave heating and drying.

|

Advantages Of Microwave drying of insects |

|

|

1 |

Microwave insect dryer can sterilize, prevent mildew, kill insects and keep fresh, and effectively improve the shelf life of black soldier flies. Therefore, the black soldier fly larvae industrial microwave dryer can be used for multiple purposes, effectively shortening the process flow. |

|

2 |

Microwave drying has a puffing effect on black soldier flies. If there is a subsequent process of crushing black soldier flies, it will be of great help to the crushing. Because the direction of water vapor in microwave drying and dehydration is from the inside to the outside, and the characteristics of microwave heating and drying can rapidly form water vapor pressure inside the black soldier flies, microwave heating and drying can puff the black soldier flies. |

|

3 |

Advanced technology and continuous production. The continuous black soldier fly microwave drying equipment has adjustable power, adjustable speed, instant start and stop, no thermal inertia, no radiation, and can be continuously produced 365 days a year. |

|

4 |

Energy saving and environmental protection. Microwave drying of black soldier flies is a process that converts electrical energy into microwave energy and then acts on the black soldier flies to convert them into heat energy to complete the drying process. |

Working Principle of the Insect and Bug Microwave Drying Oven

The Microwave drying of insects utilizes the power of microwave radiation to rapidly and uniformly dry insects such as black soldier fly larvae and mealworm. Within the oven's chamber, a high-powered microwave generator emits electromagnetic waves, which penetrate the insect's body, causing water molecules to vibrate and generate heat. This process effectively removes moisture from the insects, preserving their nutritional integrity and quality.

Industrial Microwave Dryer VS Gas Dryer Comparison

|

Operating Conditions |

Industrial Microwave Dryer |

Direct Fired Gas Dryer(Rotary Drum, Ring, Convection, Flash Types) |

|

Energy Source |

Electricity |

Gas |

|

Heat Penetration |

Volumetric(Uniform Throughout |

Surface To Interior Conduction |

|

Heating Rate |

Nearly Instantaneous |

Typically Slow |

|

Chemical Changes To Product |

None |

Carbonization, Maillard Reaction, Other

|

|

Dryness Control/Consistency |

Precision ,<1% Possible |

Non-Precision,3-5%Typical |

|

Color Change To Product |

None |

May Darken* |

|

Nutrient loss in product |

None |

Possible |

|

Reliability |

Very High |

Poor To Moderate |

|

Labor Requirements |

Minimal, Fully Automatic |

Usually Requires Dedicated Operator |

|

Fire/Explosion Hazard* |

None |

Possible |

|

Energy Efficiency |

|

|

|

|

||

|

Overall Energy Efficiency |

75%+ |

<50%** |

|

Heat Energy Delivered To Load |

95%+ |

<50% |

|

Water Removal Energy |

1000 - 1200 Btu/ Lb |

1800-2400 Btu/b** |

|

|

|

4200-5600 |

|

|

2300-2800 Kj/Kg |

Kj/Kg** |

|

Emissions |

||

|

Control Equipment Required? |

No |

Yes |

|

Generates Vocs ? |

No |

Yes |

|

Generates Cox And Nox ? |

No |

Yes |

|

Generates Particulates ? |

No |

Yes |

Technical Parameters Of Yellow Mealworm Microwave Dryer Machine

|

|

Technical Parameters Of Yellow Mealworm Microwave Dryer Machine |

|||||

|

|

Model |

Size L*W*H(Can be customized according |

Output |

Dewaterability |

Sterilization |

Baking and Roasting capacity |

|

|

LY-10KW |

5000mm*825mm*1750mm |

≥10KW |

10KG/Hour |

100KG/Hour |

30-50KG/Hour |

|

|

LY-20KW |

8000mm*825mm*1750mm |

≥20KW |

20KG/Hour |

200KG/Hour |

60-100KG/Hour |

|

|

LY-30KW |

8500mm*1160mm*1750mm |

≥30KW |

30KG/Hour |

300KG/Hour |

90-150 KG/Hour |

|

|

LY-40KW |

10000mm*1160mm*1750mm |

≥40KW |

40KG/Hour |

40KG/Hour |

120-200KG/Hour |

|

|

LY-50KW |

12500mm*1160mm*1750mm |

≥50KW |

50KG/Hour |

500KG/Hour |

150-250KG/Hour |

|

|

LY-60KW |

13500mm*1450mm*1750mm |

≥60KW |

60KG/Hour |

600KG/Hour |

180-300KG/Hour |

|

|

LY-70KW |

13500mm*1500mm*1750mm |

≥70KW |

70KG/Hour |

700KG/Hour |

210-350KG/Hour |

|

|

LY-80KW |

13500mm*1650mm*1750mm |

≥80KW |

80KG/Hour |

800KG/Hour |

240-400KG/Hour |

|

|

LY-100KW |

16800mm*1650mm*1750mm |

≥100KW |

100KG/Hour |

1000KG/Hour |

300-500KG/Hour |

|

|

LY-150KW |

22400mm*1850mm*1750mm |

≥150KW |

150KG/Hour |

1500KG/Hour |

450-750KG/Hour |

|

|

LY-200KW |

27000mm*1850mm*1750mm |

≥250KW |

250KG/Hour |

2500KG/Hour |

750-1250/Hour |

|

|

LY-300KW |

32000mm*1850mm*1750mm |

≥300KW |

300KG/Hour |

3000KG/Hour |

900-1500KG/Hour |

|

|

Power Supply |

380V±10% 50Hz±1% Three-Phase Five-Wire |

||||

|

|

Microwave Output Frequency |

2450±50Mhz |

||||

|

|

Microwave Input Apparent Power |

≤168Kva |

||||

|

|

Microwave Output Power |

≥120Kw |

||||

|

|

Microwave Power Adjustment Range |

0-30Kw(Adjustable) |

||||

|

|

Ambient Temperature |

-5-40°C |

||||

|

|

Relative Humidity |

≤80%, Surrounding Environment:No Corrosive Gas, Conductive Dust And Explosive Gas |

||||

|

|

Transmission Speed |

0-10m/Min(Adjustable) |

||||

Advantages of the Microwave drying of insects Compared with traditional drying

Enhanced Efficiency: Shandong Loyal's mealworm microwave drying machine boasts exceptional efficiency, significantly reducing drying times compared to traditional methods. Its advanced technology ensures uniform drying, resulting in superior product quality.

Nutritional Preservation: Unlike conventional drying techniques that may degrade nutritional content, microwave drying preserves the nutritional value of insects. This is crucial for applications in animal feed, pet food, and human consumption.

Versatility: The mealworm microwave drying machine is designed to accommodate various insect species and sizes, offering flexibility to manufacturers in diverse industries. Its adjustable settings allow precise control over drying parameters for optimal results.

Cost-Effectiveness: By reducing energy consumption and minimizing product waste, Shandong Loyal's yellow mealworm microwave dryer machine technology offers a cost-effective solution for insect processing operations.

Environmental Sustainability: With its energy-efficient design and reduced carbon footprint, the Insect and Bug microwave drying oven aligns with sustainable manufacturing practices, contributing to environmental conservation efforts.

FAQs: Insect and Bug Microwave Drying Oven

Q1: Can the Insect and Bug microwave drying oven accommodate large volumes of insects?

A1: Yes, Shandong Loyal's microwave insect dryer is available in various sizes to meet the production needs of different manufacturers, from small-scale operations to large-scale industrial facilities.

Q2: Is microwave drying suitable for all types of insects?

A2: While microwave drying is highly effective for many insect species, it's essential to consult with experts or conduct trials to determine the optimal drying conditions for specific insects.

In conclusion, the Insect and Bug microwave drying oven by Shandong Loyal Industrial Co., Ltd., represents a game-changing solution for the efficient and high-quality drying of insects. Its innovative technology, combined with the expertise of the manufacturer, ensures superior performance and reliability. Whether for animal feed, pet food, or human consumption, this advanced equipment sets the standard for insect processing in the modern age.

Related Processing

| Introduction of heat energy conversion during drying and cooling of pet feed |

Related Videos

| Industrial Dryer for Yellow Mealworm Drying |

| The drying of yellow mealworm |

Related News

| 800 Kg/H Industrial Microwave Locust Grasshopper Drying Baking Oven Machine For Sale In Russia |

| Microwave Conveyor Belt With 500KG/H Grasshopper Larvae Drying Machine Oven Will Be Shipped To Indonesia |

| Pet Feed Microwave Sterilization Equipment - Shanghai Mr. Xu visit |

Product Categories

- Industrial Microwave Oven

- Food Extruder Machine

- Biscuit Making Machine

- Fried Dough Extruder Machine

- Industrial Hot Air Dryer

- Feed Production Line

- Instant Noodle Machine

- Vegetable Processing Machine

- Industrial Deep Fat Fryer

- Industrial Popcorn Machine

- Nutrition Bar Manufacturing Equipment

- Automatic Packaging Machine

- Soya Nuggets Extruder

- Modified Starch Machine

- Edible straw making machine

- Doritos chips making machine

- Dog Food Manufacturing Equipment

- Corn Flakes Production Line

- Corn Puff Snacks Production Line

- Nutritional Baby Rice Powder Food Machine

- Kurkure Manufacturing Machine

- Bread Crumb Machine

- Artificial Rice Production Line

- Pellet Snack Making Machine

- Macaroni Production Machine

- Potato Chips Machine

- Wafer Line

- Cold Pressed Pet Food Machine

Contact Us

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+86 13256674591

- Email[email protected]

- WhatsApp+86 13256674591

- WeChat13256674591

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -The Qihe Yellow River Material Warehouse, No. 689, Meili North Road, Jinan City, Shandong Prov

150Kw Fully Automatic Industrial Continuous Microwave Shrimp Drying Machine

150Kw Fully Automatic Industrial Continuous Microwave Shrimp Drying Machine Continuous Tunnel Honeysuckle Flower Drying Dehydrator Machine Tunnel Microwave Baking And Sterilizing Equipment

Continuous Tunnel Honeysuckle Flower Drying Dehydrator Machine Tunnel Microwave Baking And Sterilizing Equipment Automatic Microwave Frozen Meat Beef Thawing Machine

Automatic Microwave Frozen Meat Beef Thawing Machine Hot Sale Industrial Stainless Steel Gelatin Microwave Dryer

Hot Sale Industrial Stainless Steel Gelatin Microwave Dryer