- Shandong Loyal Industrial Co.,Ltd.

- Industrial Microwave Oven Food Extruder Machine Biscuit Making Machine

Home> Processing> Introduction Of Extrusion Technology

Introduction Of Extrusion Technology

2020-12-28 12:05:57The material containing a certain amount of moisture is pushed by the screw in the sleeve of the extruder and blocked by the discharge abrasive and the intercepting device in the sleeve.

1. The Mechanism Of Extrusion Technology

The material containing a certain amount of moisture is pushed by the screw in the sleeve of the extruder and blocked by the discharge abrasive and the intercepting device in the sleeve. In addition, it is also affected by the friction heat from the outside and the material and the screw and the sleeve. The heating effect keeps the material at a high temperature of 3-8MPa and 120-200℃, and can reach a higher temperature according to needs.

Because the pressure exceeds the saturated vapor pressure at the extrusion temperature, the material will boil and evaporate water in the extrusion barrel. Under such high temperature, shearing force and pressure, the material presents a molten state. When the material is forced out of the die, the pressure suddenly drops to normal pressure. At this time, the water flashes, resulting in a situation similar to "explosion" and the product expands.

The moisture evaporates from the material and takes away a lot of heat, so that the material instantly drops from the high temperature during the extrusion process to a relatively low temperature of 80°C. Due to the decrease in temperature, the material is solidified and formed from the state during extrusion and maintains the expanded shape.

The main ingredient of extruded food is starch. Therefore, the formation of the puffed state is mainly completed by starch. In the high temperature and high pressure state, the starch granules first gelatinize, and then under the action of high temperature and high shear, the molecules combine and crosslink each other to form a network structure. The structure becomes the skeleton of the puffed food structure after being extruded, cooled and solidified, and the ingredients in other raw materials are filled in it. Therefore, the content of starch in the raw material directly affects the degree of puffing of the product. When there is no starch in the raw material, the puffing effect is basically not produced.

2.The Characteristics Of Extrusion Technology

1) Improve practical quality, easy to store

The use of puffing technology can make corn and sorghum, which originally contained more cellulose and vitamins, the rough and hard tissue structures become puffy and soft. The Maillard reaction produced during the puffing process increases the color, aroma and taste of food. Thereby improving the practical quality, so that the food has a unique flavor of light weight, crispness and strong fragrance. To

2) Improve product quality and reduce harmful substances

The extrusion process is a typical high-temperature, high-pressure, and short-term process, which limits the material handling, so almost all the nutrients in the raw materials are retained in the final product. At the same time, the high temperature and short time process can still reduce the bad product factors like harmful enzymes and microorganisms.

3) Wide applicability of raw materials and many types of products

There are many kinds of raw materials that can be processed. It can not only deep-process grains, potatoes, beans and other grains, make coarse grains finely, and produce exquisite snack foods; but also process fruits, vegetables, spices and some animal proteins. When producing puffed snacks, the same extruder only needs to change the raw materials and the die to produce products with different shapes.

4) High production efficiency and low production cost

Large-scale twin-screw extruders abroad can produce dozens of tons per hour and are easy to operate. Compared with traditional cooking methods, processing products with modern extrusion technology can significantly reduce time consumption, energy consumption, labor, and plant occupation. To

5) Less waste and no waste

When using starch to make wine and sugar, the utilization rate of raw materials after puffing is over 98℅, the sugar yield increases by 12℅, and the wine yield increases by 20℅. In addition, in general, except for a small amount of raw materials used as primers when starting up and shutting down, almost no waste is discharged during the entire production process, and there is no waste of raw materials.

3. Extrusion Equipment

The extruder was developed from a simple molding machine. At first, it was only used in the plastics industry, and then gradually used in food and other industries. The currently used extruders are mainly screw extruders, which can be divided into two types, single screw and twin screw according to their structure.

▄Single-screw extruder relies on a screw whose pitch is gradually narrower from finer to thicker to propel the material. At present, the single-screw extruder produced in my country basically uses a screw with a shallow thread height, and the rotation speed is 300-400r/min. It can produce high grinding and high shearing force, and the time for the grain raw materials to stay in the barrel is only 10-20s, the temperature of the material before being ejected from the mold is as high as 130-140℃.

▄The twin-screw extruder has a pair of reverse or co-rotating screws that continuously mesh with each other, and the material is forced to be conveyed by the principle of positive displacement. In the process of material transportation, pressure reflux is rarely formed, which can increase the local pressure sharply, speed up the expansion process, and obtain high output.

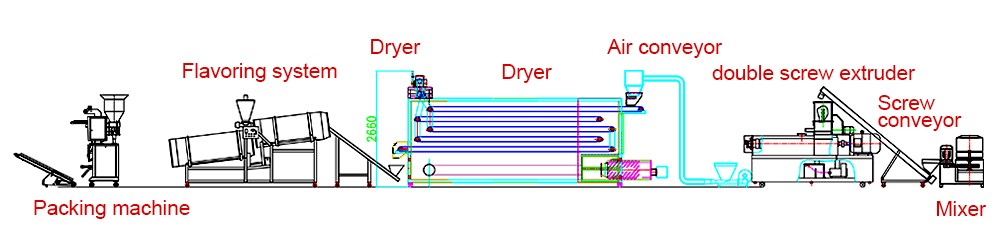

4. The Extrusion Process

The production process of extruded food is as follows: raw material → peeling → crushing → mixing (wetting) conditioning → conveying → feeding → extrusion cooking, puffing → shaping, cutting → baking → spraying, seasoning → packaging.

1) Crush

In order to mix the raw materials uniformly and fully gelatinize the starch during extrusion and cooking to facilitate puffing, each material (corn and germ should be removed first) is crushed to a particle size of 30-40 mesh, and the material of the twin-screw extruder is crushed to 60 mesh the above.

2) Mixed conditioning

Different raw materials and auxiliary materials are mixed uniformly in a humidifier according to a certain proportion, and the amount of water is determined according to the climate, environmental temperature and humidity, and the moisture of the mixed raw materials is controlled at 13% to 18%. To

3) Extrusion

Extrusion is the key to the entire process, which directly affects the texture and taste of the product. There are many variables that affect extrusion expansion, such as the moisture content of the material, the temperature, pressure, screw speed during the extrusion process, the type of raw material and its ratio, etc. Generally speaking, the moisture content of the material is between 13% and 18%. The temperature is about 120~160℃, the pressure of the extrusion chamber is 0.5~1MPa, the screw speed is 800~1000 r/min, and the residence time of the material in the extruder is 10~20s.

Raw materials with low amylose content will have a high α degree after puffing, and the puffing effect will be better. Different protein and fat content in the materials also affect the puffing quality. Materials with high protein content will have a low puffing degree during extrusion; when the fat content exceeds 10%, the puffing rate of the product will be affected, and a certain amount of fat can improve the product Texture and flavor. Different types and models of extruders have different optimal process parameters for extrusion

4) Shaping and cutting

After the puffed material is extruded from the die hole, it is cut into a shape by a rotary cutter close to the die hole or pulled to a shaping machine. After roll forming, the puffed material is cut into rolls, cakes and other puffed semi-finished products with the same length and uniform thickness. .

5) Baking

The extruded semi-finished product has a high moisture content and needs to be sent to a tunnel oven through a belt conveyor for further baking. The moisture content is less than 5% to extend the shelf life. At the same time, it produces a special fragrance after baking to improve quality .

6) Seasoning

In a rotary seasoning machine. The vegetable oil and cream mixed in a certain proportion are heated to about 80 ℃, and the oil is evenly sprayed on the surface of the material that is tumbling with the rotation of the seasoning machine through the mist nozzle. The purpose of the oil spray is to improve the taste; the other is to make the material stick to the seasoning easily.

Then the seasoning is sprayed, and the powdered seasoning is evenly sprinkled on the surface of the continuously rolling material through a powder sprayer equipped with a screw propeller to obtain the finished product. To prevent moisture and ensure crispness, the seasoned products should be packed immediately.

5. Application Of Puffing Technology In Pet Food

The application of extrusion technology to pet food originated in the 1950s.

Dry puffed pet food is usually produced as extruded puffed food. The material enters the warehouse to be puffed after two-stage pulverization and two-time mixing, and then enters the extruder for extruding and puffing after sufficient conditioning. At the same time, grease, pigment, meat slurry, etc. can be added to the conditioner to avoid the problem of high-oil or high-moisture materials after being added in the mixer. After extrusion, the water content of the material is 20% ~ 30%, and it is pneumatically conveyed to the dryer for drying. The dried material enters the intermittent spraying machine, which can spray grease, food attractant and fragrance powder. The high temperature of feed pellets just after drying is conducive to the uniform distribution of grease. After adding grease to the feed, the internal water content is not easy to volatilize, and the water content of the attractant is also high. The drying strength of the dryer should be increased accordingly before spraying. After spraying, the material enters the cooler for cooling, the moisture drops below 9%, and the temperature drops to close to room temperature.

After the pellets leave the finished product warehouse, a screening process is performed to control the crushed particles and powder in the product to an ideal range, and finally the pellets are packaged by a packing scale. Pet food pellets are generally conveyed by pneumatic conveying or inclined belt conveying to reduce residues during processing.

The extrusion and expansion of pet food can be extruded by a single-screw extruder or twin-screw extruder. The single-screw extruder is suitable for some low-grade pet foods with low fat content in the formula. The water content during extrusion is generally 22% ~ 28%. However, when the content of fresh meat in the formula reaches 20% ~ 30%, it is difficult for a single-screw extruder to provide the strong mixing and shear required during the extrusion process. At this time, the advantages of a twin-screw extruder will be highlighted. Compared with a single-screw extruder, a twin-screw extruder can add almost twice the content of fat to pet food, and the feed formula contains 12% fat.

The processing technology of semi-moist pet food is similar to that of dry puffed pet food, but the by-products of meat or meat slurry are added and mixed before extrusion. The typical extrusion water content is between 30% and 35%. Its soft fleshy feel usually does not reduce moisture. The formula of soft puffed pet food is similar to that of semi-moist pet food, so the processing equipment is similar to it, and the processing technology is similar to that of dry pet food. The finished product has an expanded shape similar to that of dry puffed feed, and it also has the softness of semi-moist pet food. And flexible sensuality.

Pet snacks can generally be divided into four types: puffed snacks, non-puffed snacks, filled puffed snacks and joint puffed snacks. Special equipment is often required for production. Puffed snacks can be produced with standard pet material puffing steps; non-puffed snacks are processed using semi-wet technology, and the equipment uses an extruder (single-screw or twin-screw extruder can be used); filled puffed snacks require an extruder Some ingredients in the formula are matured, and fillers that do not need to be matured are added through the pump system. In the production of joint puffing snacks, two puffing machines need to be combined through a common set of molds, and each puffing machine produces a product with a formula.

Twin Screw Food Extruder Machine

Twin Screw Food Extruder Machine Pet Food Extruder Machine

Pet Food Extruder Machine Japanese panko bread crumbs making machine

Japanese panko bread crumbs making machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Instant Pasta Production Line

Instant Pasta Production Line