- Shandong Loyal Industrial Co.,Ltd.

- Industrial Microwave Oven Food Extruder Machine Biscuit Making Machine

Home> Processing> Application of soybean protein production line

Application of soybean protein production line

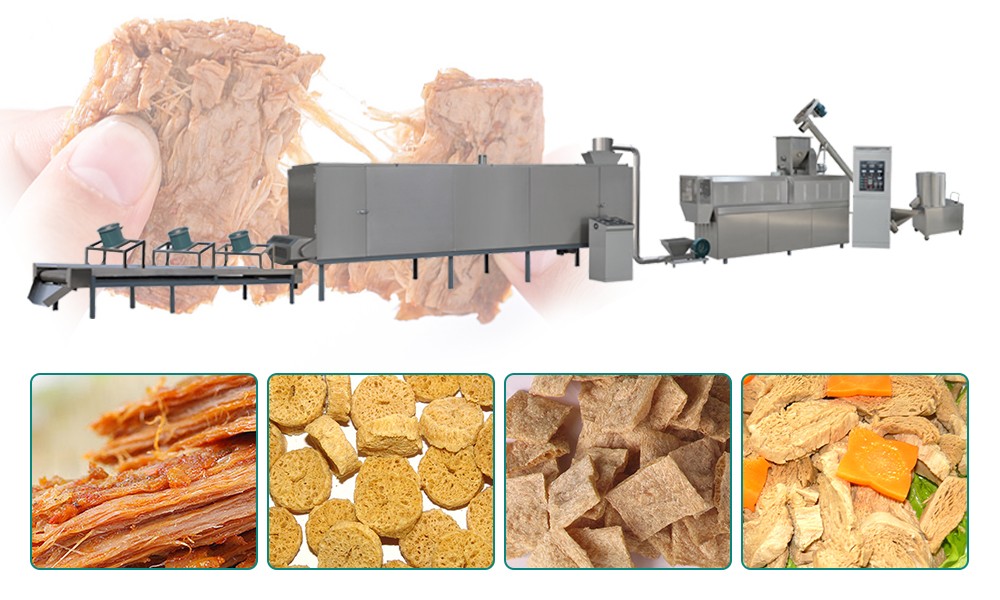

2021-12-27 11:34:31The soybean extruder machines uses defatted soybean meal and peanut meal as the main raw materials, which are stirred, squeezed and sheared to form a layered fiber structure; its product has a high protein content, has a meaty state and taste, and has the characteristics of oil absorption, water absorption, and taste absorption; Free of cholesterol and animal fat.

The soybean extruder machines uses defatted soybean meal and peanut meal as the main raw materials, which are stirred, squeezed and sheared to form a layered fiber structure; its product has a high protein content, has a meaty state and taste, and has the characteristics of oil absorption, water absorption, and taste absorption; Free of cholesterol and animal fat. It can be widely used in meat products, fast food, quick-frozen food, and can also be made into various vegetarian snack foods and vegetarian dishes. Soya protein food processing line also be named TVP/TSP/FVP(Textured vegetarian soy protein/ Fiber protein) is deisgned with our rich experiences on food extruder industry.

The production line has following features: many models, flexible equipment configuration, wide range of raw materials, a wide variety of final products, and simple operation. By changing the cutters, it can produce different kinds of protein shapes to meet customer requirements. This kind of product is popular with vegetarians.

The production line has following features: many models, flexible equipment configuration, wide range of raw materials, a wide variety of final products, and simple operation. By changing the cutters, it can produce different kinds of protein shapes to meet customer requirements. This kind of product is popular with vegetarians.

Full fat soya extruder machine can produce different protein content products by changing formulations. Soya bari manufacturing plant produce a kind of vegetarianism with meat like flavor and texture taste, also known as tissue protein. You can get different structure and different shapes protein products, such as soya nuggets, soya chunks, soya mince, etc.

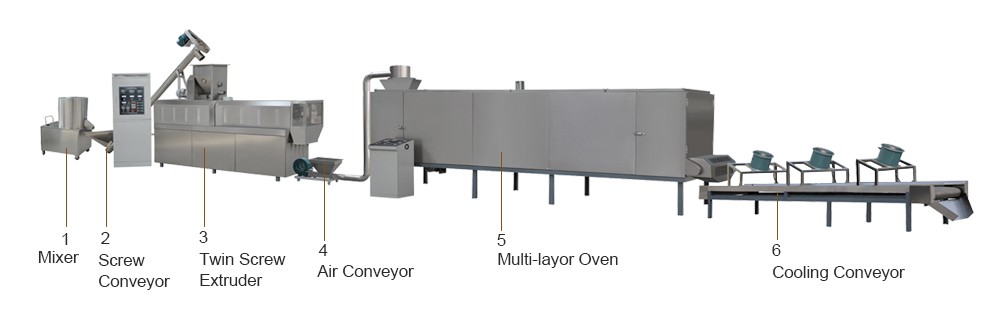

Flow Chart Of Soya Bari Manufacturing Plant:

Mixer-Screw Conveyor-Twin Screw Extruder- Air Conveyor- Multi-layor oven- Cooling machine

Soya Protein Food Processing Line Feature

|

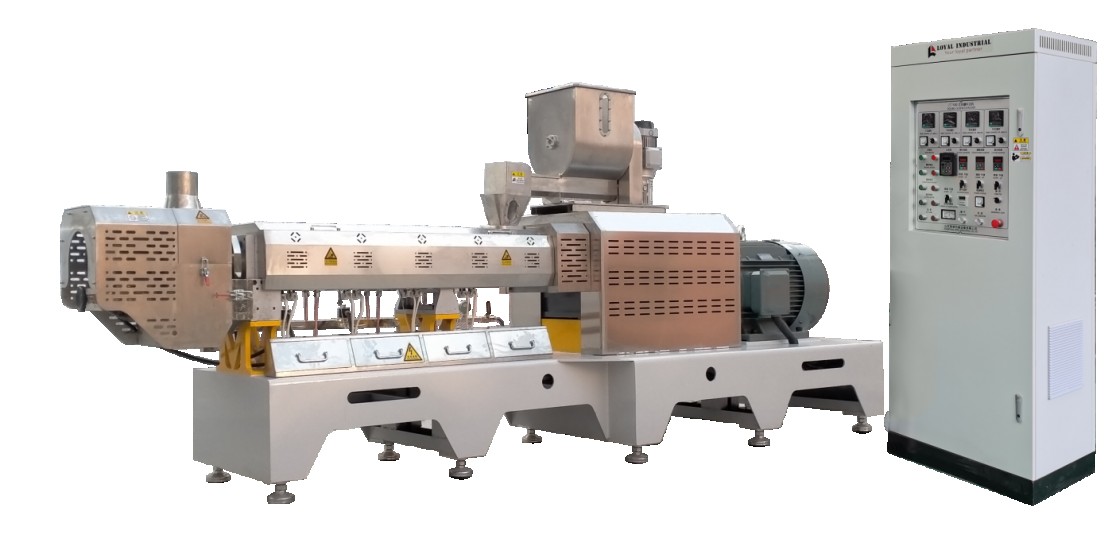

1 |

Twin screw machine is composed of feeding system, extrusion system, rotary cutting system, heating system, transmission system and control system. |

|

2 |

The screws are made by alloy steel (38CrMoAL) ,the life of the screw is longer, |

|

3 |

The gearbox has automatic lubrication function, with extends gear life. |

|

4 |

Visual automatic temperature control system to make temperature control more intuitive and parameters more clearly |

|

5 |

The double screw has a self-cleaning function, no need to remove the screw out to clean it when the machine is stopped |

|

6 |

Different screw and length-diameter ratio can meet different production processes. |

Full fat soya extruder machine is mainly through a twin-screw extruder, defatted soybeans, concentrated soybean protein or separated soybean protein are added with a certain amount of water and additives to mix uniformly, and the raw materials are pushed in the barrel by the twin screw, and in the screw and barrel It is forced to heat, pressurize, and squeeze out to make it into a protein molecule. Soybean pieces are arranged neatly, produce tissue structure in the same direction, and at the same time coagulate to form fibrin, and the chewing feeling is similar to that of meat.

Technical Parameter Of Soybean Extruder Machines:

|

Model |

Extruder Power |

Output |

Extruder Dimension |

|

LY65-TVP |

45 kw |

100~150kg/h |

3600x1000x2000mm |

|

LY 65 |

45kw |

120~160kg/h |

3200×1000×1800mm |

|

LY 75-TL |

140 kw |

200~300kg/h |

5200x1000x1900mm |

|

LY 75-E |

125 kw |

400~500kg/h |

5900x1000x1900mm |

|

LY 85-V |

110 kw |

300-400 kg/h |

5900x1000x1900mm |

|

LY 100 |

160 kw |

1000kg/h |

5700*1300*2500mm |

Applications

(1)Dry Textured soya protein Pellets, Crumbs, Minced, Flakes, Chunks, Chips, Schnitzel, Nuggets.

(2)High moisture wet protein Soya,pea, Pea-sunflower

Advantages of soy protein:

1. Adding 10-20% silk protein to meat products can replace beef and pork without affecting the quality of the product and reducing the cost of raw materials.

2. It can prevent the atrophy of meat quality and has higher nutritional value.

3. Textured soy protein contains natural antioxidants. After adding textured soy protein to meat products, it can play a protective role and reduce oxidative deterioration.

4. In recent years, as a new type of plant protein, vegetarian soybean meat is replacing pork and beef, and is widely used in meat products, spicy foods, and snacks.

|

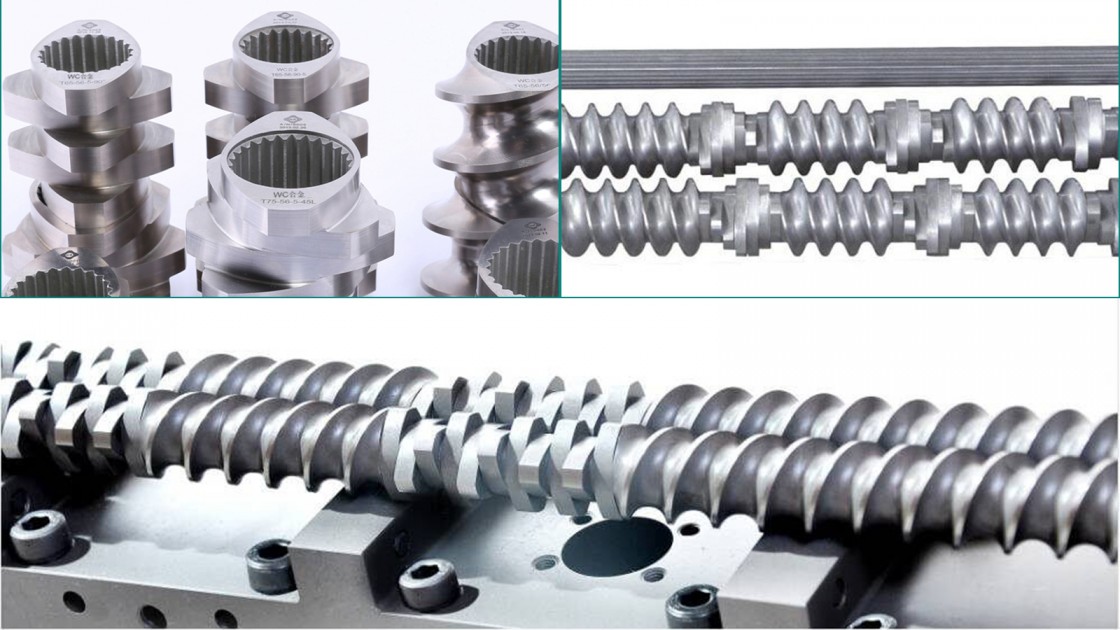

1 |

Screw made by nit-riding process, high strength and wear-resting. |

|

2 |

Self-cleaning ability, no need to discharge or clean the barrel and screw when roasting or replacing of materials. |

|

3 |

Adopting speed adjusted converter on feeding system, extrusion system and cutting system. |

|

4 |

Food grade stainless steel twin screw feeding machine, stable materials feeding in the whole food process. |

|

5 |

Gearbox with automatic lubrication function, extending gear life. |

|

6 |

World famous brand Siemens main motor, guaranteeing good quality. |

|

7 |

Increased radiator on driving part for forced cooling effect, ensuring extruder operates safely. |

|

8 |

Barrel with water-cooled circulation, raw materials not only for corn/rice, also for wheat flour/starch with high viscosity. Different moisture-extrusion temperature ratio, whole-expanded and half expanded as different type of products. |

|

9 |

Different screw and length-diameter ratio can meet different production processes. |

Japanese panko bread crumbs making machine

Japanese panko bread crumbs making machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Instant Pasta Production Line

Instant Pasta Production Line