- Shandong Loyal Industrial Co.,Ltd.

- Industrial Microwave Oven Food Extruder Machine Biscuit Making Machine

Home> Processing> How is textured vegetable protein made

How is textured vegetable protein made

2021-12-27 11:21:48Soybean protein made by soya bari machine, is a kind of plant protein. The amino acid composition of soy protein is similar to that of milk protein. Except for slightly lower methionine, the content of other essential amino acids is relatively rich. It is a plant-based complete protein. In terms of nutritional value, it can be equivalent to animal protein by soya bari machine. It is also the closest to human body in terms of genetic structure. Amino acids, so it is the most nutritious plant protein.

How is textured vegetable protein made

一、 Brief introduction of Soybean protein production line

Soybean protein made by soya bari machine, is a kind of plant protein. The amino acid composition of soy protein is similar to that of milk protein. Except for slightly lower methionine, the content of other essential amino acids is relatively rich. It is a plant-based complete protein. In terms of nutritional value, it can be equivalent to animal protein by soya bari machine. It is also the closest to human body in terms of genetic structure. Amino acids, so it is the most nutritious plant protein.

二、What is Soybean protein?

Textured soy protein is a food prepared from soy protein isolate and soy defatted soy flour as raw materials. The defatted soy, 70% protein soy flour, isolated soy protein, etc. are mixed with water, food additives, etc., and then crushed, stirred , heated and directly Steam enhanced pretreatment, and then physical treatments such as mixing, extrusion in soya nuggets extruder, shearing, and forming are carried out through an extrusion extruder. Shandong Loyal industrial have 18 years experience on the soyabean chunks making machine. Soyabean chunks making machine At the same time, the raw materials are sterilized during the extrusion process, protein organization, starch alphaization, and enzyme passivation. Chemical treatment such as melting, high temperature treatment, cooling, drying and other heat treatments, as the globulin in the separated protein and soybean defatted soybean meal is converted into silk protein and fibrin, the protein content is above 50%. If the dried food is adjusted After being hydrated or rehydrated, there is still a bite (bite strength, chewing bite) that is sufficiently similar to meat.

Because of its good water absorption and oil retention, 25-50% tissue protein is added to minced meat or other meat products to make dishes that have a meaty taste. Therefore, it can be used as a meat substitute. Adding to meat products can increase the color, aroma and taste of meat products, increase protein content, and promote particle integrity. Therefore, it is also an ideal meat product additive. It can also be used as an auxiliary material for fast food or added to foods such as sausages. middle. Soy protein contains natural antioxidants. After adding tissue protein to meat products, it can play a protective role and reduce oxidative rancidity. In addition, the tissue protein has a good granular structure. After hydration during production, it has uniform tissue characteristics and specific tissue structure (flaky, filamentous). After soaking, and then adding appropriate seasonings, it can be prepared Into various flavors of vegetarian food. Therefore, the soy protein is a real high-quality and inexpensive food. It will be a good choice to invest soyabean chunks making machine

Because of its good water absorption and oil retention, 25-50% tissue protein is added to minced meat or other meat products to make dishes that have a meaty taste. Therefore, it can be used as a meat substitute. Adding to meat products can increase the color, aroma and taste of meat products, increase protein content, and promote particle integrity. Therefore, it is also an ideal meat product additive. It can also be used as an auxiliary material for fast food or added to foods such as sausages. middle. Soy protein contains natural antioxidants. After adding tissue protein to meat products, it can play a protective role and reduce oxidative rancidity. In addition, the tissue protein has a good granular structure. After hydration during production, it has uniform tissue characteristics and specific tissue structure (flaky, filamentous). After soaking, and then adding appropriate seasonings, it can be prepared Into various flavors of vegetarian food. Therefore, the soy protein is a real high-quality and inexpensive food. It will be a good choice to invest soyabean chunks making machine

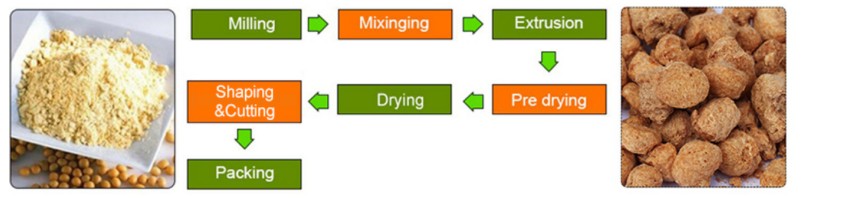

三、Process of Soybean protein production line

Mixer-Screw Conveyor-Twin Screw Extruder- Air Conveyor- Dryer- Hoister- - Cooling machine

The edible soybean meal is processed into defatted soybean powder through a worm wheel grinder, and the defatted soybean powder that meets the specifications is mixed with 25-30% process water to enter the extruder. In this process, the soybean product is squeezed in a spiral shape under high temperature and high pressure from 20% of moisture, and then rapidly squeezed out of atmospheric pressure to become a dry soybean product by soya bari machine.

Under high pressure, the oil in soybeans becomes free. Soybean tissues are completely destroyed in the process of pressure reduction. The digestibility is improved. The harmful physiological substances in soybeans are inactivated by heat, and the inherent beany smell of soybeans is removed. And odor, the product can be made into fibrous, porous structure, sponge and other special structure products, and then packaged after cooling and drying.

四、 parameters and output of the soybean protein production line

|

Model |

LY-65 |

LY-70 |

LY80 |

|

Installed Power |

90kw |

110kw |

150kw |

|

Power Consumption |

70kw |

90kw |

130kw |

|

Capacity |

100-150kg/h |

150-200kg/h |

300-350kg/hr |

|

Dimension |

19x2x3.5m |

32x2.5x3.5m |

38*4.5*6.5m |

五、Sample of the soybean protein production line

六、Advantage of the soybean protein production line

Soybean protein has two main characteristics:

One is nutrition and partial functionality. Under normal circumstances, the soybean protein content of the finished product can reach about 50 after the soya nuggets extruder, and the fat content is about 1%, which is an ideal low-fat and high-protein food. In terms of protein content, it is more than 2 times that of meat, 3 times that of eggs, and 12 times that of milk, so it enjoys the reputation of "vegetable meat"; and has strong water and oil absorption.

The second is economy, low price, and wide application range. New soybean protein foods that can be used directly as cooking materials from the food industry to home cooking.

Japanese panko bread crumbs making machine

Japanese panko bread crumbs making machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Instant Pasta Production Line

Instant Pasta Production Line