- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Processing> What Are The Basic Functions And Main Features Of The Extruder Machine?

What Are The Basic Functions And Main Features Of The Extruder Machine?

2021-04-21 17:55:50The principle of the extruder machine is that mechanical energy is converted into heat energy. The heat generated when the machine rotates is used to squeeze and mature food.

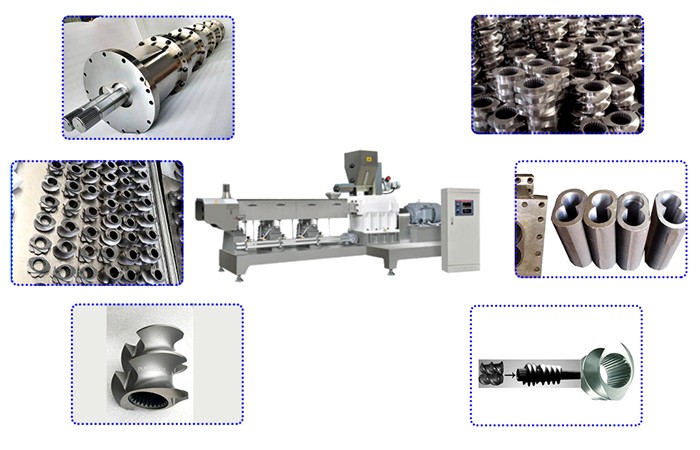

The principle of the extruder machine is that mechanical energy is converted into heat energy. The heat generated when the machine rotates is used to squeeze and mature food. The most obvious feature of expanded food is its larger volume. So what are the basic functions and main features of the extruder? Next, take the pet feed extruder making machine as an example to analyze the characteristics of the extruder.

The multiple functions of the extruder make it widely used in feed, food, industry and other fields. Based on the extruder (dry, wet, single screw or twin screw), we will introduce one or a group of functions in the process of extruder.

The multiple functions of the extruder make it widely used in feed, food, industry and other fields. Based on the extruder (dry, wet, single screw or twin screw), we will introduce one or a group of functions in the process of extruder.

These functions are:

1. Cohesion: In the process of puffing, food or feed ingredients can be closely combined and condensed into discrete small pieces.

2. Degassing effect: Food or feed materials containing air bubbles will be removed during the expansion process.

3. Dehydration: During the expansion process of general food or feed, the water content will lose 4%-7% on the original basis.

4. Expansion: The operating conditions and configuration of the extruder can control the density (such as sinking or floating) of pet feed and aquatic feed.

5. Gelation: Puffing cooking can gelatinize starch (from various sources, such as tubers or grains) during the processing of food or pet feed.

5. Gelation: Puffing cooking can gelatinize starch (from various sources, such as tubers or grains) during the processing of food or pet feed.

6. Grinding function: During the processing of food or feed, the raw materials can be ground to a certain extent in the extruder.

7. Homogenization: The homogenization of the extruder changes the structure of unattractive raw materials and makes them more acceptable.

8. Mixing effect: During the expansion process, various extruders have a variety of screws to choose from, which can make the extruder produce the desired mixing amount.

8. Mixing effect: During the expansion process, various extruders have a variety of screws to choose from, which can make the extruder produce the desired mixing amount.

9. Pasteur sterilization and sterilization: In the process of food or feed puffing, the raw materials can be pasteurized or sterilized by puffing technology.

The main features of the extruder are:

The main features of the extruder are:

1. The model design is novel, the structure is compact, and the production efficiency is high.

2. Reliable work, sturdy and durable, low failure rate, convenient operation and maintenance.

3. Simple and convenient to use, stable transmission and low noise.

4. The main components are made of special alloy materials by heat treatment, with long service life and low feed cost.

5. Dry puffing process adopts self-heating method without steam system.

6. The screw design has a strong self-cleaning function, and the screw groove can be purified by itself, so when changing the formula and product variety, there is no need to stop the machine for cleaning. The screw has a strong pumping effect, and the material has a strong stagnation and diffusion effect, and the advancing speed is relatively high. Fast, the product quality is relatively stable.

7. The screw discharge nozzle adopts a modular design, which is convenient to adjust and low in price.

8. It can be equipped with an automatic feeding system. The feeder is a horizontal conveying screw controlled by the latest switched reluctance speed motor in the world. The other end is connected with an extruder, and the output can be controlled by adjusting the feeding amount. (Quantitative feeding, and can effectively prevent material arching).

9. Cutting system, the independent cutting device is connected to the machine body conveniently and quickly, and the cutting head with variable speed can easily adjust the cutting knife, and the gap between the cutting knife and the template can be easily adjusted. Different templates can be prepared according to the needs to ensure that all The required material diameter and length can produce products of different specifications and material shapes.

10. No adhesive is needed for processing floating feed, and it can maintain stability in water for more than 2 hours.

11. It can process round products of ¢1-20 mm (the template is customized according to needs).

12. The main shaft is a combined structure, and the spare extension shaft can adapt to the puffing processing of different raw materials.

13. Small and medium-sized equipment is especially suitable for scientific research institutions, special breeding farms or small and medium-sized feed factories.

14. Wet and dry dual purpose. In the single-screw extruder equipment above 30KW, the conditioner can be used for wet puffing, and both have the capability of both dry and wet.

Twin Screw Food Extruder Machine

Twin Screw Food Extruder Machine Single Screw Extruder Food Processing Machine

Single Screw Extruder Food Processing Machine Pet Food Extruder Machine

Pet Food Extruder Machine Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines