- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Processing> What Is The Working Principle And Composition Of The Twin Screw Extruder?

What Is The Working Principle And Composition Of The Twin Screw Extruder?

2020-09-22 09:47:21The powdery raw material is transformed from powder to paste through the extruder machine. And then gelatinized and cracked. The raw fiber is partially degraded and refined. It can not only effectively kill microorganisms, bacteria, etc..

The powdery raw material is transformed from powder to paste through the extruder machine. And then gelatinized and cracked. The raw fiber is partially degraded and refined. It can not only effectively kill microorganisms, bacteria, etc.. But also under strong pressure. Under the influence of poor, the instant the material becomes pasty is ejected from the die hole, an extruded product with a loose structure is formed. And the bad factors are passivated to improve the appearance of the twin screw extruder machine product.

Currently, we sell two types of screw extruder machine. One is a single-screw extruder. And the other is a twin-screw extruder machine. Compared with the former, the advantage of twin screw extruder is relatively more obvious for raw material extrusion and expansion.

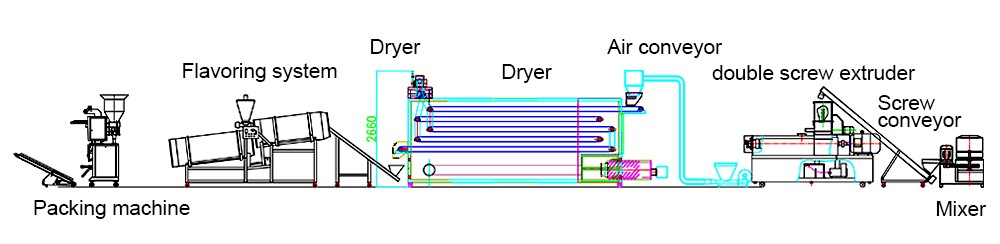

Generally speaking, a twin screw extruder machine is composed of feed, extrusion, heating, and rotary cutting.

The cavity of the double screw extruder machine adopts a multi-section building block type. Each cavity can independently control the temperature. And there are heating and cooling channels inside. According to user requirements, steam and electric heating methods can be used. The temperature is automatically controlled to control the temperature of the extruder machine product. Convenient, more accurate, to ensure the taste and quality of the twin screw extruder product.

Because the twin screw extruder machine adopts spiral forced feeding, the feeding is even. And the uneven input of raw materials is avoided to affect the expansion effect of the extruded product.

Currently, puffed food, bean products and other industries need to be processed through extrusion processes and use professional extrusion machines to better ensure the loose taste of extruded products.

Twin Screw Food Extruder Machine

Twin Screw Food Extruder Machine Single Screw Extruder Food Processing Machine

Single Screw Extruder Food Processing Machine Pet Food Extruder Machine

Pet Food Extruder Machine Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines